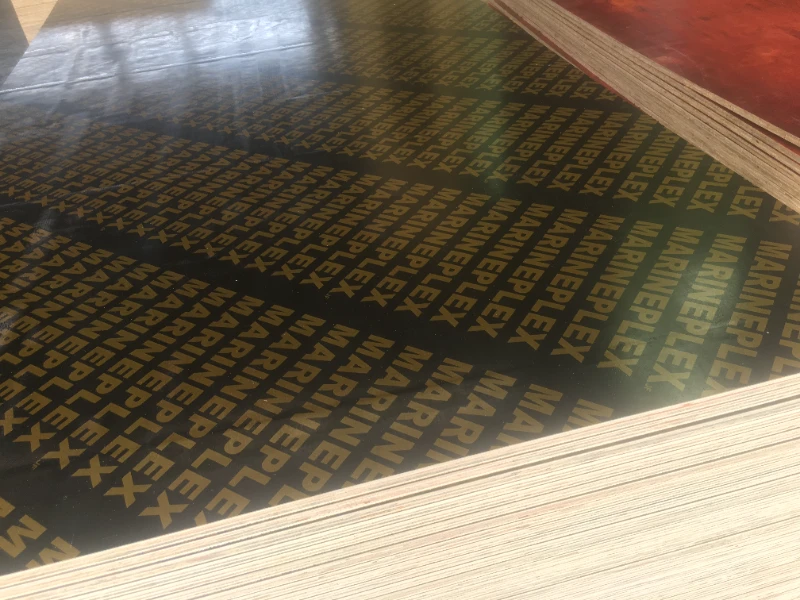

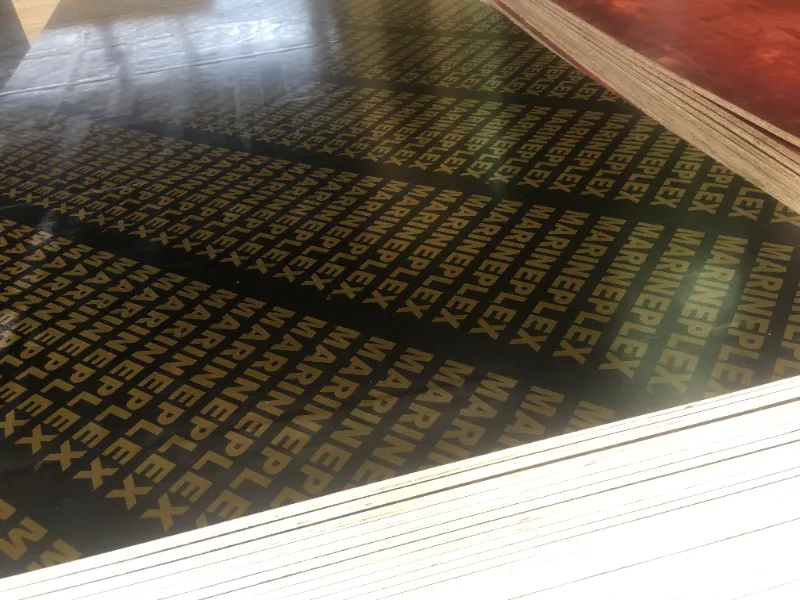

It is widely used, moisture-proof and green, and can be used as single or double veneer treatment. It is often used for interior decoration, packaging materials, and furniture materials.

Product Description

1. Stable quality, wide range of uses, wall decoration, furniture materials, packaging materials.

2. Green and environmental protection, strict implementation of formaldehyde emission grading standards.

3. The veneer can be customized, Okoume, elm, birch, etc.

4. WPB/WR/MR/INT, four types of plywood can be customized according to the demand.

5. We have 20 years of production experience in plywood products, a full set of advanced equipment imported from Germany, and complete product certificates.

6. Customize the selection of tree species and glue according to user requirements, and the utilization rate reaches 100%.

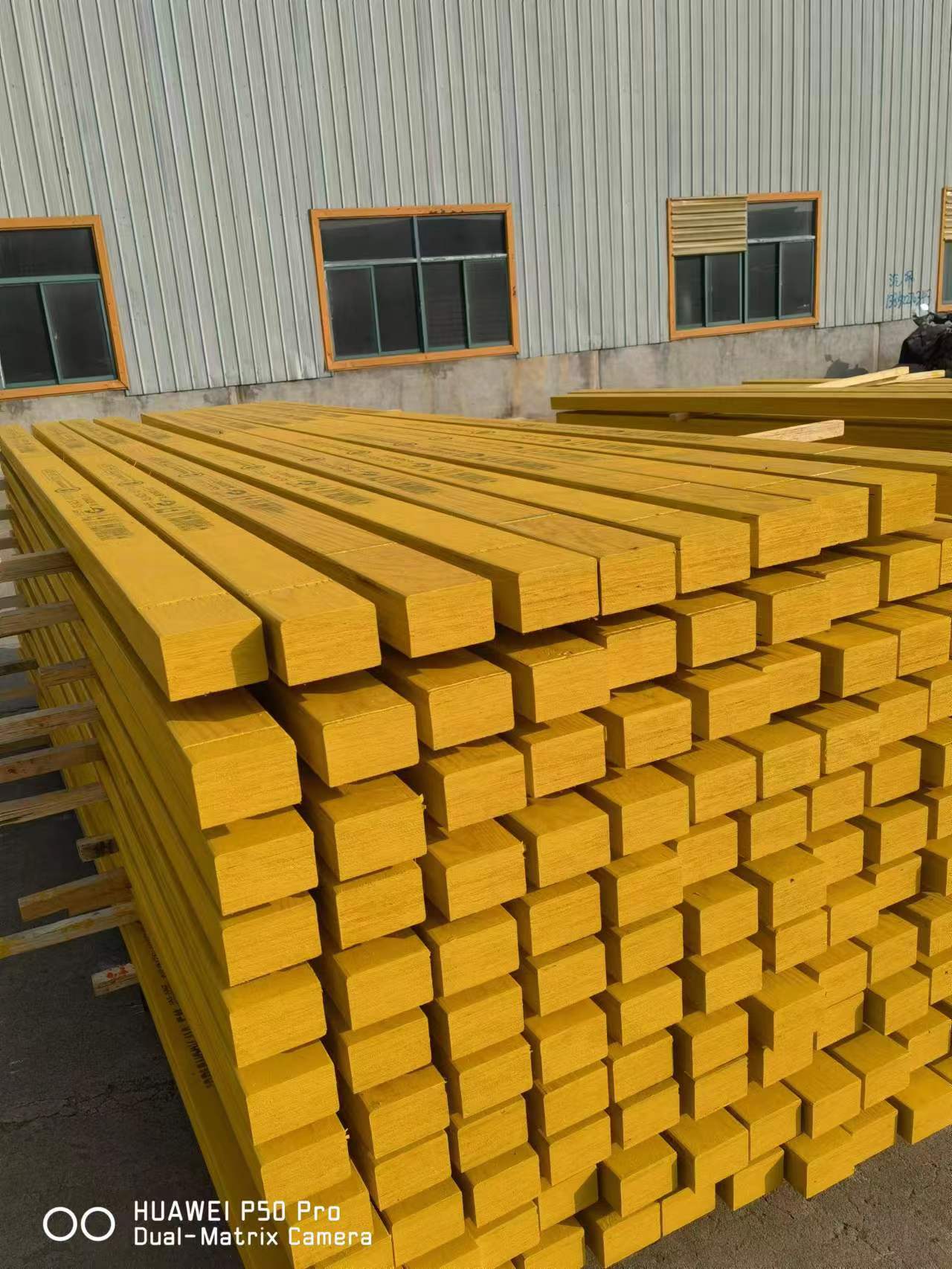

Product Parameters

| Place of Origin | Jiangsu, China |

| Main Material | Pine,eucalyptus, Poplar |

| Grade | FIRST-CLASS, Construction |

| Usage | Outdoor |

| Design Style | Contemporary |

| Application | Other, Building Construction |

| Project Solution Capability | Graphic design, 3D model design, total solution for projects, Others |

| After-sale Service | Online technical support |

| Warran ty | 3 Year |

| Formaldehyde Emission Standards | E0,E1,E2,as request |

| Core | Pine,eucalyptus, Poplar |

| Veneer Board Surface Finishing | Double-Sided Decoration |

| Glue | MR/E0/E1/E2/WBP/Melamine or as request |

| Thickness | ±0.50mm/customized |

| Certification | CE FSC CARB/EPA BSI-AS/NZS4357 |

| Moisture | 8-13% |

| SIZE | L≤2440mm,W≤1220mm |

Product Knowledge

1. Classification of general plywood?

Plywood for general use, classified according to product characteristics, WPB-boiling water-resistant plywood; WR-water-resistant plywood; MR-moisture-resistant plywood; INT-non-water-resistant plywood.

2. What is veneer plywood?

A wood-based panel made of natural wood veneer laminated to plywood. Decorative veneer is a thin wood chip made of high-quality wood by slicing or rotary cutting; because of its beautiful and natural surface, it is mostly used for interior decoration and furniture manufacturing.

3. How to judge the quality of plywood from the appearance?

The wood grain of good-quality plywood is relatively clear, and it feels smooth and flat, without cracking and other phenomena. The core is an important factor that determines the quality of the plywood. It can be tapped by hand. If the sound is uneven, it means that the core is hollow.

4. About the moisture content of plywood?

The moisture content of the board is very important. If the moisture content is too high, the board is prone to cracking and deformation.

5. What are the differences in adhesives?

There are three main types of plywood adhesives used in plywood production. Melamine glue: moisture-proof, and has a certain resistance to boiling and weathering, and cannot be frequently soaked in water. Phenolic glue: extremely excellent water resistance and weather resistance. Urea-formaldehyde glue: moisture-proof glue, can not be used outdoors, less used.

Product Display & Application