Plywood. It's a ubiquitous material in construction and DIY projects, but what truly sets it apart is its remarkable strength and stability. This article delves into the dimensional stability of plywood and its inherent durability, explaining why this engineered wood product is a superior choice for a wide range of applications. Understanding these key features is crucial for making informed decisions, whether you're a construction company owner like Mark Thompson in the USA or a building material supplier. We'll explore the science behind plywood's resilience and why it's a material worth considering for your next project.

1. What Exactly is Plywood and Why is it So Widely Used?

Plywood is a versatile and reliable material for a wide range of construction and woodworking projects. It's an engineered wood product made from thin layers or thin sheets of wood veneer, called ply or layers of veneer, bonded together with adhesive. These thin layers of wood veneer are stacked with their grain direction alternating, a process that significantly enhances the strength and stability of the resulting plywood sheet. Plywood is commonly used because it offers a unique combination of exceptional strength, durability, and dimensional stability, making it superior to solid wood in many applications. From floor underlayment to roof sheathing and furniture construction, plywood finds its place due to its ability to withstand stress and resist warp. Let’s explore further why this wood product has become such an integral part of the construction industry.

2. Understanding Dimensional Stability: What Makes Plywood Resist Warping?

Dimensional stability refers to a material's ability to maintain its original dimensions when subjected to changes in humidity and temperature. This is a critical factor, especially in construction, where materials are constantly exposed to varying environmental conditions. One of the key advantages of plywood is its excellent dimensional stability. Unlike solid wood, which is prone to warp, swell, and shrink significantly with changes in humidity, plywood exhibits far less movement. This is primarily due to its unique cross-laminated construction. The alternating grain direction of the thin sheets of veneer effectively cancels out the natural tendency of wood to expand or contract along the grain. This inherent resistance to dimensional change ensures that the plywood maintains its shape and integrity over time, preventing issues like uneven surfaces or structural weaknesses.

3. How Does the Layered Structure of Plywood Contribute to its Exceptional Stability of Plywood?

The layered structure of plywood is the cornerstone of its remarkable stability of plywood. Plywood typically consists of an odd number of layers or odd number of plies, with each ply running perpendicular to the layers of veneer above and below it. This cross-graining technique is crucial. When wood absorbs moisture, it expands most significantly across the grain. By orienting adjacent layers of wood veneer at right angles, the expansion and contraction forces are counteracted. This crisscross pattern creates a balanced and incredibly stable panel. The layered structure not only minimizes warp but also distributes stress more evenly across the plywood panels, enhancing their overall structural integrity. This ingenious design plays a crucial role in why plywood remains flat and true, even under stress or fluctuating humidity and temperature.

4. Why is the Dimensional Stability of Plywood Crucial for Structural Applications?

For structural applications, the dimensional stability of plywood is not just a desirable feature; it's a necessity. In applications like wall sheathing, roof decking, and subflooring, the ability of the material to maintain its dimensions under varying humidity and temperature is paramount for the overall integrity of the building. If the plywood were to significantly expand or contract, it could lead to problems such as buckling, cracking of finishes, and even compromise the structural integrity of the building envelope. Plywood’s resistance to movement ensures a stable and reliable base for other building materials. For construction companies like Mark Thompson's, using dimensionally stable plywood minimizes costly callbacks and ensures the longevity and safety of their projects. Our structural ply, for example, is engineered precisely for these demanding uses.

5. Beyond Dimensional Stability: What Contributes to Plywood's Impressive Durability?

While dimensional stability is a key advantage, plywood also boasts impressive durability. Several factors contribute to this. The cross-laminated construction, which enhances stability, also significantly increases the strength of plywood compared to solid wood. The alternating grain pattern makes it less likely to split or crack along the grain. Furthermore, the adhesive used in plywood production plays a critical role. Modern high-quality adhesives create a strong bond between the layers of veneer, making the plywood resistant to delamination, even under stress or in moist conditions. Depending on the intended use, plywood may also undergo treatments to further enhance its durability, such as adding preservatives for resistance to rot and insect infestation. This combination of structural design and material science makes plywood a long-lasting and reliable material for a wide array of applications.

6. Plywood Panels vs. MDF: Which Offers Better Strength and Stability?

When comparing plywood panels to mdf (Medium-Density Fiberboard), a key difference lies in their strength and stability. While mdf offers a smooth surface ideal for painting and intricate millwork, plywood generally provides superior structural performance. Plywood’s cross-laminated construction gives it significantly higher bending strength and resistance to impact compared to mdf, which is made from compressed wood fibers. Regarding stability, plywood is also less susceptible to changes in size and shape due to moisture. Mdf tends to absorb moisture more readily, leading to swelling and a loss of integrity. Therefore, for applications where strength and durability are paramount, such as structural framing, flooring, and sheathing, plywood is the preferred choice. However, for applications prioritizing a smooth, paintable surface and intricate detailing, mdf might be more suitable.

7. What Are the Different Types of Plywood Available and Their Specific Applications of Plywood?

The world of plywood is diverse, with various plywood types designed for specific purposes. Understanding these differences is crucial for selecting the right plywood for your project. Some common plywood types include:

- Structural Plywood: Engineered for load-bearing applications, offering high strength and stability. Ideal for framing, subfloors, and roof sheathing. Our range of structural ply options caters to these demanding needs.

- Hardwood Plywood: Features a hardwood veneer on the face, providing an attractive finish for furniture, cabinetry, and interior paneling.

- Softwood Plywood: Typically made from pine or fir, commonly used for construction purposes due to its cost-effectiveness.

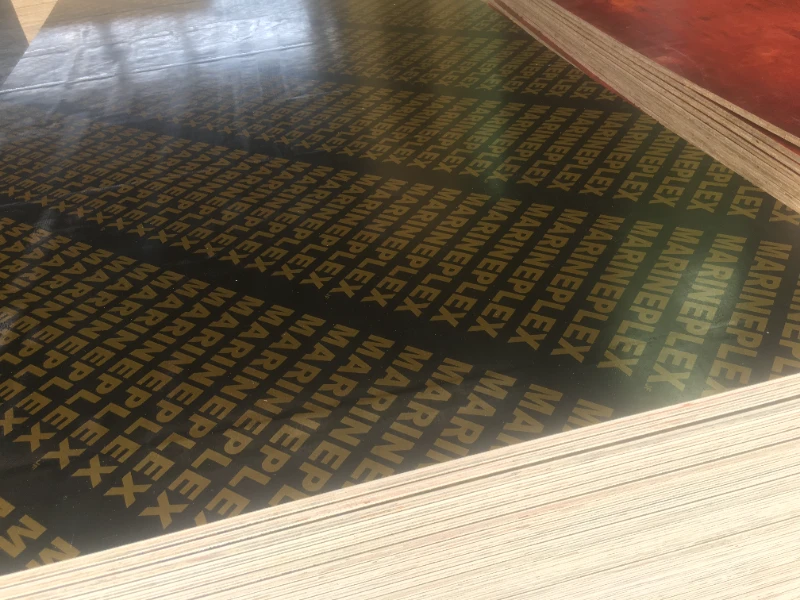

- Film Faced Plywood: Coated with a resin-treated paper, providing a smooth, durable surface resistant to water and abrasion. It's widely used in concrete formwork, like our Formply, and applications requiring a high-quality finish.

- Marine Plywood: Constructed with waterproof plywood adhesives and often made from durable timbers, making it suitable for boat building and other marine applications.

- Non-Structural Plywood: Used for decorative or non-load-bearing applications like interior paneling, crafts, and packaging. We offer a variety of options for non-structural plywood.

Each type possesses unique characteristics, making plywood a versatile material for a wide range of projects.

8. How Does Grade Plywood Affect its Strength of Plywood and Durability?

Plywood is graded based on the quality of its veneer faces. The grading system, often using letters like A, B, C, and D, indicates the number and size of permissible defects, such as knots and repairs, on the face and back veneers. Higher grade plywood, like A-grade, will have a smooth, blemish-free surface, making it suitable for applications where aesthetics are important, such as furniture or cabinetry. Lower grade plywood, like C or D-grade, may have more visible defects but still offer excellent structural performance. The grade primarily affects the appearance and surface quality, but it can indirectly impact durability. For instance, grade plywood with fewer repairs might offer a more consistent surface for finishes, potentially extending the lifespan of the finished product. However, for structural applications, the strength of plywood is largely determined by the wood species, the thickness of the ply, and the quality of the adhesive, rather than solely by the surface grade.

9. Can Waterproof Plywood Offer Superior Dimensional Stability in High-Humidity Environments?

Yes, waterproof plywood, often referred to as marine plywood or exterior-grade plywood, is specifically designed to offer superior dimensional stability in areas with high humidity and even direct water exposure. The key difference lies in the adhesive used. Unlike interior-grade plywood, which uses urea-formaldehyde adhesives, waterproof plywood utilizes phenol-formaldehyde or similar water-resistant adhesives. These adhesives create a much stronger and more moisture-resistant bond between the layers of veneer, preventing delamination even when exposed to moisture. While all plywood benefits from its cross-laminated construction in terms of dimensional stability, waterproof plywood takes it a step further by resisting moisture absorption, which is a primary cause of expansion and contraction in wood products. This makes it an ideal choice for outdoor applications, boat building, and projects in environments with consistently high humidity.

10. How to Choose the Right Plywood for Your DIY Projects and Professional Needs?

Selecting plywood for your specific project requires careful consideration of several factors. First, determine the intended use. Is it for structural support, like framing or flooring? Or is it for a non-structural application like cabinetry or decorative panels? This will help you narrow down the appropriate plywood types. Consider the environmental conditions. Will the plywood be exposed to moisture or high humidity? If so, waterproof plywood or exterior-grade options are necessary. Think about the required strength and durability. For heavy-duty applications, choose thicker plywood with a higher grade if surface appearance matters. For diy projects, cost can be a factor, so balance your needs with your budget. Finally, check for relevant certifications and standards, especially for structural applications, to ensure the plywood meets building codes and safety requirements. Understanding these factors will guide you in choosing the right plywood that provides the optimal combination of performance, durability, and cost-effectiveness for your needs. You can explore our extensive range of plywood options to find the perfect fit for your project.

Key Takeaways:

- Plywood's layered construction with alternating grain direction is the key to its exceptional dimensional stability, resisting warp and movement due to changes in humidity.

- This dimensional stability is crucial for maintaining the structural integrity of buildings and other constructions.

- Plywood offers superior strength and durability compared to solid wood and mdf for many applications.

- Different types of plywood are available, each tailored for specific uses, from structural applications to decorative purposes.

- The grade of plywood primarily affects its surface appearance, while the adhesive type determines its water resistance.

- For projects in high-humidity environments or with direct water exposure, waterproof plywood is essential for maintaining dimensional stability.

- Careful consideration of the intended use, environmental conditions, and required strength and durability is crucial when selecting plywood.

For high-quality LVL Timber, Film faced plywood, Structural Plywood, and more, partner with a reliable supplier. At Jsylvl, we are a factory specializing in engineered wood products, committed to providing top-tier materials for your construction and manufacturing needs. Contact us today to discuss your project requirements.

Post time: Jan-15-2025