Choosing the right plywood for your project can feel like navigating a lumber jungle, right? This article is your friendly map, guiding you through the world of plywood sizes and thickness. We'll break down the different types of plywood, explain why plywood thickness matters, and help you select the perfect plywood sheet for any job. Think of it as unlocking the secrets to working with one of the most versatile building materials out there! Whether you're a seasoned builder or a weekend DIY enthusiast, understanding plywood thickness is key to a successful project. Let's dive in and make sense of it all!

1. What Exactly is Plywood and Why Does the Thickness of Plywood Matter?

Plywood is a fantastic building material made by gluing together thin layers of wood veneer. Imagine stacking slices of wood on top of each other, with the grain of each slice running in a different direction. This clever construction is what gives plywood its strength and stability, making it much less likely to warp or split compared to solid lumber. Because plywood is manufactured this way, it's a reliable choice for all sorts of projects.

Now, why does thickness matter? Think of it like this: a thin piece of paper is easy to bend, but a stack of paper (making it thicker) is much harder to fold. The thickness of the plywood directly impacts its strength, stiffness, and how well it can hold screws or nails. Whether you're building sturdy shelves, crafting durable furniture, or constructing walls, the plywood thickness needs to be just right for the job. The right plywood thickness ensures your project is not only strong but also safe and long-lasting.

2. What are the Standard Plywood Sizes You'll Commonly Find?

When you head to your local home improvement stores or lumber yard, you'll find that plywood comes in standard sizes, making it easier to plan your projects. The most common plywood size you'll see is 4 x 8 feet. This standard sheet of plywood is widely used in construction and DIY projects because it's a manageable size for transportation and handling.

But plywood also comes in other plywood sizes. You might find smaller sizes 2 x 2 feet for smaller crafts or repairs. Larger plywood sizes available like 4 x 10 feet are also available for bigger projects where you need fewer seams. Understanding these standard plywood sizes helps you estimate how much material you need and reduces waste. Think about your project's scale – are you building a small birdhouse or a whole shed? Knowing the standard size options helps you choose efficiently.

3. How is Plywood Thickness Actually Measured? Understanding Nominal and Actual Thickness.

Here's a little secret about plywood thickness: what you see on the label isn't always the actual thickness. This is because of something called "nominal" vs. "actual" dimensions. Nominal thickness is the name given to the thickness, like "half-inch" or "three-quarter inch." However, during the manufacturing process, the plywood may shrink as it dries, and the sanding process can also remove a tiny bit of material.

So, the actual thickness of plywood is often slightly less than the nominal thickness. For example, a plywood labeled as 3/4 inch might actually measure closer to 11/16 inch. While this difference might seem small, it can be important for projects where precise measurements are crucial, like fitting pieces together or using specific hardware. Always best to check the actual thickness if precision is key for your project. This is a common practice in the plywood industry.

4. What are Some Common Types of Plywood and Their Typical Thickness?

The world of plywood is vast, with different types of plywood designed for specific purposes. Let's explore a few common ones and their typical thickness ranges:

- Structural Plywood: This type is designed for strength and is common for home construction, used for walls, roofs, and floors. Common thicknesses range from 1/4 inch to over 1 inch. Our structural ply, like the 18mm structural ply, is a reliable choice for building projects.

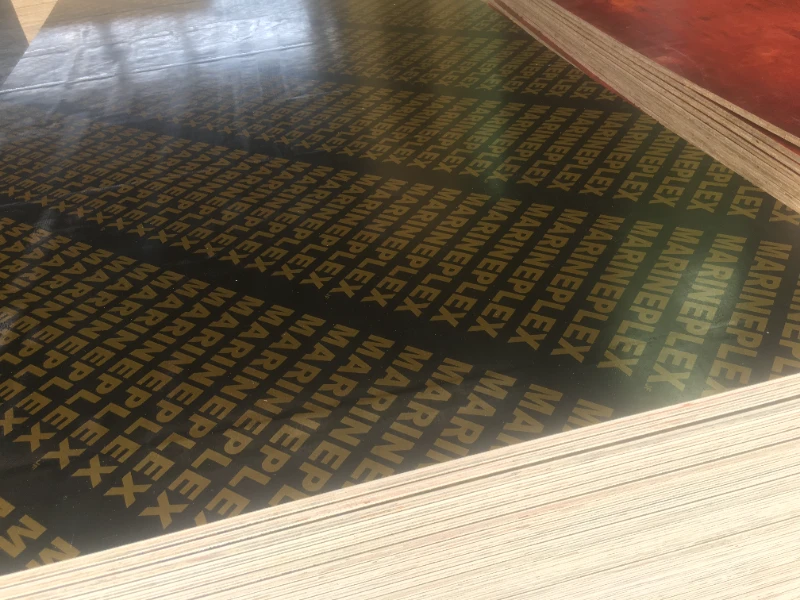

- Film Faced Plywood: This plywood has a special coating that makes it water-resistant and smooth, perfect for concrete formwork. You'll find film faced plywood in thicknesses like 12mm, 15mm, and 18mm. Consider our Phenolic film faced plywood 16mm for your next formwork job.

- Non-Structural Plywood: This is a more general-purpose plywood, often used for furniture, crafts, and interior projects. Non structural plywood comes in a variety of different thicknesses, from thin 1/8 inch sheets to thicker options like 3/4 inch. We offer a range, including 12mm non structural plywood.

- Hardwood Plywood: Made with a hardwood veneer on the surface, this type of plywood is prized for its appearance and is used for cabinetry and fine furniture. Hardwood plywood is also available in different thicknesses.

- OSB Board (Oriented Strand Board): While not technically plywood, OSB is a similar sheet good made from compressed wood strands. It's often used for sheathing and subfloors and comes in common thicknesses like 1/2 inch, 5/8 inch, and 3/4 inch. We supply various osb board thicknesses, such as osb board 18mm.

The type of plywood you need will often dictate the appropriate thickness.

5. Why is Choosing the Right Plywood Thickness Crucial for Your Project?

Selecting the right size and thickness of plywood isn't just about aesthetics; it's about the functionality and longevity of your project. Imagine building shelves with paper-thin plywood – they wouldn't hold much, would they? Similarly, using overly thick plywood where it's not needed can add unnecessary weight and cost.

For projects requiring strength and support, like flooring or roofing, thicker plywood is essential. This ensures the surface can withstand weight and pressure without bending or breaking. For decorative applications or smaller crafts, thinner plywood might be sufficient and easier to work with. The use of the plywood dictates the thickness of the plywood you need. Think about the load your project will bear and the environment it will be in. This will help you determine the plywood thickness that provides the best balance of strength, weight, and cost. Choosing the plywood you need carefully is a smart move.

6. Sheet of Plywood Less Than You Expected? Understanding Thickness Variations.

It can be a bit frustrating to buy a sheet of plywood labeled a certain thickness and find it measures slightly less. As we discussed earlier, this is due to the difference between nominal thickness and actual thickness. The manufacturing process, including drying and sanding, inevitably removes a small amount of material.

While manufacturers aim for consistency, slight variations can occur between different batches or even within the same sheet. This is why it's always a good idea to measuring the plywood yourself, especially for critical applications. Understanding that often the actual measurement is less than the nominal thickness can save you headaches down the road. If your project requires a very specific exact thickness, you might need to factor in these potential variations or even look for specialty sizes or pre-sanded options.

7. Exploring Different Plywood Core Types: How Does the Core Affect Thickness?

The inside of a plywood sheet, known as the plywood core, plays a significant role in its overall properties, including thickness. Different plywood core types utilize different types of wood and construction methods.

- Veneer Core: This is the most common type, where the core layers are made of wood veneer, similar to the face veneers. The thickness and quality of these core veneer layers influence the plywood's stability and strength.

- Lumber Core: In this type, the core is made of solid lumber strips glued together. This results in a very strong and stiff plywood, often thicker than veneer core plywood.

- Particleboard Core: This core is made from compressed wood particles. It's generally less expensive but also less strong and can be more prone to moisture damage. Plywood with a particleboard core might have a more uniform thickness.

- MDF (Medium-Density Fiberboard) Core: Similar to particleboard but with finer wood fibers, MDF cores offer a smooth surface but are also less resistant to moisture.

The common type of plywood core will influence the final thickness of the sheet and its overall performance. For instance, plywood with a lumber core is typically thicker than hardwood plywood with a veneer core. The least expensive plywood core is often particleboard.

8. Beyond the Basics: Do Specialty Plywood Sizes Exist?

While standard plywood sizes like 4 x 8 feet are readily available, the plywood industry also offers specialty sizes to cater to specific needs. These might include:

- 5 x 5 feet: This size is sometimes used in specific construction or furniture making applications.

- Oversized Sheets: For large-scale projects, you might find plywood in sizes exceeding the standard sheet of plywood is 4 x 8 feet, helping to minimize seams.

- Longer Sheets: Plywood can also be found in longer lengths, such as 10 feet or even longer, useful for continuous runs in construction.

- Custom Cuts: Many suppliers offer cutting services, allowing you to get plywood cut to your exact plywood dimensions.

If your project has unique size plywood requirements, it's worth exploring the availability of these plywood sizes available. Contacting a specialized plywood supplier or your local home improvement stores can help you find what you need.

9. Tips for Measuring the Plywood Thickness Yourself.

Ensuring you have the right size and thickness starts with accurate measurement. Here are a few tips for measuring the plywood yourself:

- Use Calipers: For the most precise measurements, use a digital or dial caliper. These tools can measure the thickness down to fractions of a millimeter or inch.

- Use a Ruler or Measuring Tape: While less precise than calipers, a good quality ruler or measuring tape can give you a good estimate of the thickness. Measure at several points across the plywood sheet to account for any minor variations.

- Measure from the Edge: Place your measuring tool firmly against the edge of the plywood for the most accurate reading.

- Check Multiple Sheets: If you're using multiple plywood sheets, measure a few of them to ensure consistency.

- Account for Finish: If the plywood has a finish, remember that the finish adds a tiny bit to the overall thickness.

Taking the time for accurate measuring the plywood will help you avoid issues during your project.

10. Where Can You Find the Plywood You Need in the Right Size and Thickness?

Finding the plywood you need in the right size and thickness is usually straightforward. Here are common places to look:

- Home Improvement Stores: Large retailers like Home Depot or Lowe's offer a wide selection of common plywood types and sizes.

- Lumber Yards: Local lumber yards often have a more extensive inventory, including specialty plywood and a wider range of thicknesses. They may also offer cutting services.

- Specialty Plywood Suppliers: For less common plywood types or sizes, consider contacting businesses that specialize in plywood and other sheet goods. As a factory specializing in engineered wood products, we at Jsylvl (https://www.jsylvl.com/) can provide a variety of plywood options.

- Online Retailers: Many suppliers sell plywood online, offering convenience but potentially higher shipping costs.

Remember to consider the grade of the plywood as well as the thickness when making your selection. For example, for projects needing high strength, consider our structural plywood options like 15mm Structural Plywood F11 (https://www.jsylvl.com/15mm-structural-plywood-f11/). If your project involves concrete, our Concrete plywood (https://www.jsylvl.com/concrete-plywood/) is designed for that purpose. And for applications needing a smooth surface, our film faced ply 15mm (https://www.jsylvl.com/film-faced-ply-15mm/) could be ideal.

Key Takeaways:

- Plywood thickness is crucial for the strength and stability of your project.

- Standard plywood sizes like 4x8 feet are readily available, but specialty sizes exist.

- Understand the difference between nominal thickness and actual thickness.

- Different types of plywood come in available in various thicknesses to suit specific applications.

- Always measuring the plywood yourself can help ensure accuracy.

- Consider the plywood core types as they impact thickness and other properties.

- Source your plywood from reputable suppliers to ensure quality and the right type of plywood.

- For projects where appearance matters, sanded plywood provides a smoother surface.

- Remember that plywood is a necessity in countless construction and woodworking endeavors.

By understanding the nuances of plywood sizes and thickness, you'll be well-equipped to tackle your next project with confidence and achieve excellent results! Happy building!

Post time: Jan-07-2025