Understanding Plywood Core Types: Your Guide to Choosing the Right Substrate

(A Simple Explanation for Builders and Manufacturers)

Have you ever wondered what makes plywood so strong and versatile? A big part of the secret lies in its core! This article will break down the different plywood core types in an easy-to-understand way. We'll explore everything from veneer core to lumber core, helping you choose the type of core that's perfect for your next project. Whether you're building furniture, constructing houses, or anything in between, understanding plywood cores is key to getting the best results. Let's dive in and discover the world of plywood from the inside out!

What is a Plywood Core and Why is it Important?

Imagine a sandwich. The bread on the outside gives you the surface you see and touch. But what’s inside – the filling – gives the sandwich its substance and flavor. In plywood, the core is like that filling. It's the inner layer, or layers, that sit between the face and back veneers. The core is constructed of different materials and this choice dramatically affects how the plywood performs.

Why is the core so important? Well, it determines a lot about the plywood’s overall characteristics. Think about things like strength and stability, flatness, weight, and even how well it holds screws (screw holding ability). The core influences the plywood’s resistance to bending (bending strength) and its ability to stay dimensionally stable, meaning it won't warp or twist easily. Choosing the right plywood core is crucial for ensuring your project is not only beautiful but also strong and long-lasting. As a factory specializing in engineered wood products in China, we at Jsylvl understand that the core is at the heart of quality plywood.

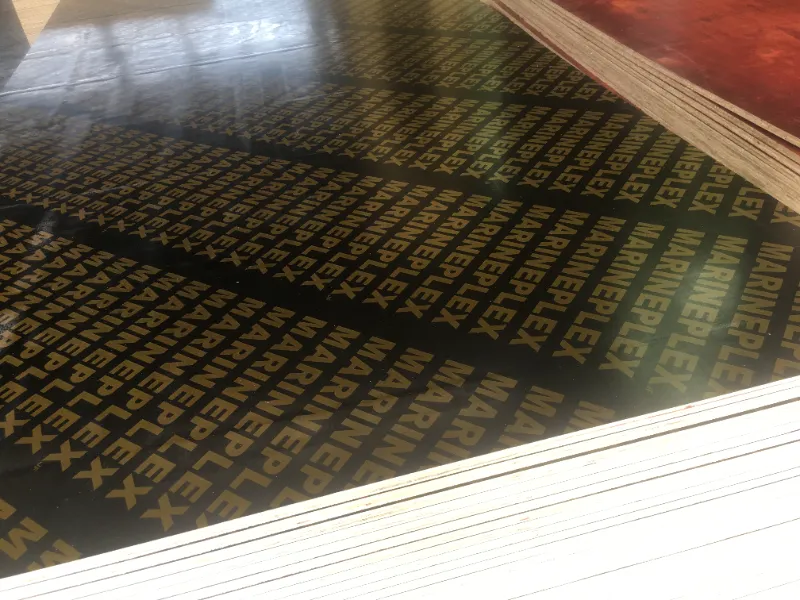

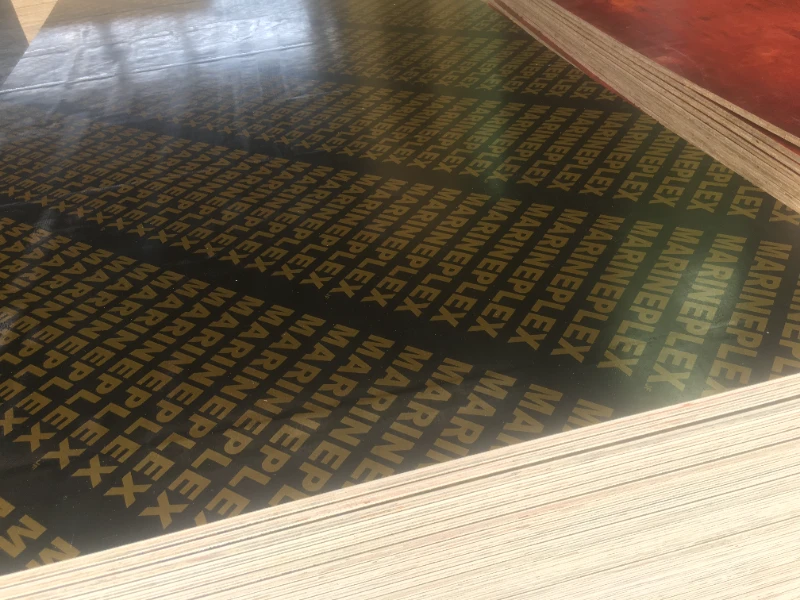

12mm Film faced plywood from Jsylvl, showcasing the importance of core quality beneath the surface.

Veneer Core Plywood: The Workhorse of the Plywood World?

Veneer core plywood is probably the most common type of core you'll encounter. Imagine taking thin sheets of wood, called veneers, and stacking them up, with the grain direction alternating grain in each layer. That's essentially what a veneer core is. These core veneers are glued together under pressure and heat to create a solid panel.

Why is veneer core plywood so popular? It's a great all-rounder! It offers good strength and stability and is generally more affordable than some other core options. Veneer core panels are lightweight, making them easier to handle and work with. Plus, the layered construction helps to resist warping and splitting, which is a big advantage. At Jsylvl, we produce a wide range of veneer core plywood, from structural plywood for construction to non-structural plywood for furniture, understanding its versatility is key to meeting diverse customer needs. For customers like Mark Thompson in the USA, veneer core plywood often represents a balance of quality and cost-effectiveness.

Lumber Core Plywood: When Strength and Screw Holding are Key?

Now, let's talk about lumber core plywood. Instead of layers of veneer, lumber core plywood has a core made from solid strips of lumber, placed edge to edge. Think of it like a mini tabletop inside your plywood. These lumber strips are usually made of softwood or poplar, and then veneer is applied to both faces and sometimes as crossbands beneath the face veneers.

What makes lumber core plywood special? Its main advantage is its exceptional screw holding capacity. If you need plywood that can really grip screws tightly, perhaps for heavy fixtures or joinery, lumber core is often the first choice. It's also very rigid and strong, making it great for applications where stiffness is important. However, lumber core plywood can be heavier and sometimes more prone to voids or gaps in the lumber core. While we offer lumber core plywood at Jsylvl, we advise customers to consider the specific needs of their project, as it may be an expensive core option compared to veneer core.

LVL scaffold planks, demonstrating the strength and reliability required in structural applications.

MDF Core vs. Particleboard Core: Understanding Composite Core Options?

Beyond wood veneer and lumber, there are also composite core options like MDF core and particleboard core. MDF stands for medium density fiberboard, and particleboard is made from wood chips bonded together with resin. Both are engineered wood products, but they have different properties.

MDF core is known for its very smooth surface, making it an excellent substrate for face veneer and paint. MDF is made from fine wood fibers, giving it a consistent density and flatness. It's also quite stable and less likely to warp. However, MDF can be heavy and doesn't hold screws as well as plywood or lumber core. Particleboard core, on the other hand, is the least expensive core option. It's made from larger wood particles and is less dense than MDF. Particleboard is suitable for applications where cost is a major concern, but it has lower screw holding strength and is more susceptible to damage from moisture. Neither MDF core nor particleboard core are typically used in structural applications, but they can be good choices for furniture components and paneling where surface smoothness is prioritized. It's important to note that both MDF and particleboard may contain formaldehyde, so choosing low-formaldehyde options is important, especially for indoor use.

Hardwood Plywood Core vs. Softwood Plywood Core: Does Wood Type Matter?

When we talk about hardwood plywood and softwood plywood, we're generally referring to the species of wood used for the face and back veneers. However, the core can also be made from hardwood or softwood veneer. Hardwood plywood often uses hardwood veneer throughout, including in the core. This can result in a denser, stronger, and more durable plywood. Examples of hardwood cores might include birch, maple, or oak veneer.

Softwood plywood, conversely, typically uses softwood veneer like pine or fir for the core veneers. Softwood plywood is generally less expensive and lighter than hardwood plywood. It's often used in construction applications where strength-to-weight ratio is important. The choice between hardwood and softwood core often depends on the intended use and budget. For decorative applications or furniture where a fine finish is desired, hardwood plywood is often preferred. For structural or utility purposes, softwood plywood can be a more economical choice.

Exploring Different Types of Veneer Cores: From Poplar to Birch?

Within veneer core plywood, there's still a lot of variation depending on the veneer species used in the core. Common core veneer species include poplar, birch, and softwood veneer like pine. Poplar core is a very common choice due to its affordability, light color, and good workability. It provides a smooth, consistent surface for the face veneer. Birch core, especially Baltic birch, is known for its exceptional strength and stability, as well as its attractive appearance. Baltic birch plywood is often praised for its void-free core and consistent veneer layers.

Softwood veneer cores, such as pine, offer a cost-effective option for applications where high strength isn't the top priority. The type of veneer used in the core can influence the plywood’s weight, density, bending strength, and even its screw-holding. For example, a plywood with a birch core will generally have better screw holding and higher bending strength than one with a poplar core. At Jsylvl, we carefully select core veneer species to match the performance requirements of different grade plywood products.

Marine plywood, often utilizing high-quality veneer cores for enhanced durability in demanding environments.

Appleply and Baltic Birch: Are These Specialty Veneer Core Panels Worth It?

Appleply and Baltic birch are often considered specialty veneer core panels. Appleply is a brand name for a plywood known for its distinctive edge appearance, showcasing the layers of veneer. It typically uses veneer from usually basswood or poplar, and it’s prized for its flatness, stability, and attractive edge detail, making it popular in furniture and fixture design where the edges are exposed as a design element.

Baltic birch, as mentioned earlier, is renowned for its exceptional quality. It's typically made from birch veneer sourced from the Baltic region. Baltic birch plywood stands out for its void-free core, consistent veneer thickness, and high number of veneer innerplies. This construction results in superior strength and stability, excellent screw holding, and a beautiful, clean edge. While Appleply and Baltic birch are generally more expensive core options, their superior performance and aesthetic qualities often justify the cost for high-end furniture, cabinetry, and architectural applications. For projects demanding the quality plywood, these specialty cores are definitely worth considering.

How Does the Core Impact Plywood Grade and Overall Quality?

The core plays a significant role in determining the grade plywood and its overall quality. Plywood grades are often based on the quality of the face and back veneers, but the core construction is also a critical factor. A high-quality core will be free of voids, overlaps, and gaps. Voids in the core can reduce the plywood’s strength, flatness, and screw-holding. Overlaps and gaps can also create unevenness and affect the plywood’s structural integrity.

Plywood manufacturers use different grading systems, but generally, higher grades indicate better face and back veneer quality and a more consistent, defect-free core. For instance, in structural grade plywood, the core must meet specific requirements for strength and stability. Even in non-structural grades, a well-constructed core contributes to the plywood’s dimensional stability, flatness, and overall workability. When sourcing plywood, it's important to understand the grading system and inquire about the core construction to ensure you're getting the quality plywood that meets your project requirements. At Jsylvl, we maintain strict quality control over our core production to ensure consistent grade plywood for our B2B customers.

Choosing the Right Plywood Core for Different Applications?

Selecting the right plywood core depends heavily on the intended application. For structural applications like wall sheathing, roofing, and subflooring, structural plywood with a strong veneer core or lumber core is essential. Consider LVL Timber (Engineered Wood Products) for even higher structural demands. For furniture making and cabinetry, veneer core plywood or MDF core plywood are popular choices. Veneer core offers a good balance of strength and workability, while MDF core provides an exceptionally smooth surface for painting or laminating. For applications requiring excellent screw holding, such as heavy-duty shelving or fixture construction, lumber core plywood is a top contender.

If moisture resistance is a concern, especially in bathrooms or kitchens, consider marine plywood, which uses special water-resistant glues and high-quality veneer core construction. For exterior applications, ensure the plywood is specifically designed for exterior use and has a suitable core and face veneers to withstand exposed to moisture and weather conditions. Thinking about the specific demands of your project – strength, screw holding, surface finish, moisture resistance, and budget – will help you find the best plywood core for the job.

Sourcing Quality Plywood Cores: What to Look For?

When sourcing quality plywood cores, whether you're a construction company or a furniture manufacturer, there are several key factors to consider. First, inquire about the type of core construction and the veneer species used in the core. Ask about the grade plywood and ensure it meets the required standards for your application. Check for certifications, such as FSC for sustainable sourcing or CARB compliance for formaldehyde emissions.

Inspect samples to assess the core for voids, overlaps, and gaps. Flatness and dimensional stability are also important indicators of quality. Consider the density and weight of the plywood, as these can affect handling and performance. For film faced plywood or formply, examine the surface for the face veneer and the quality of the phenolic or film coating. Finally, consider the supplier's reputation and their ability to provide consistent quality and reliable delivery. As a leading plywood and LVL supplier from China, Jsylvl is committed to providing high-quality engineered wood products with consistent core construction and reliable performance to meet the needs of our B2B partners like Mark Thompson in the USA and customers across North America, Europe, and Australia. Contact us today to discuss your plywood core requirements!

Key Takeaways: Plywood Core Types

- The plywood core is the inner layer that significantly impacts plywood performance.

- Veneer core is versatile and widely used, offering a good balance of properties.

- Lumber core excels in screw holding and rigidity.

- MDF core and particleboard core are composite core options, with MDF providing a smoother surface.

- Hardwood and softwood cores offer different characteristics and price points.

- Specialty cores like Appleply and Baltic birch provide premium performance.

- Core quality is crucial for plywood grade and overall performance.

- Choose the right plywood core based on your specific application needs.

- Source quality plywood cores from reputable suppliers, considering certifications and inspections.

Post time: Feb-05-2025