LVL (laminated veneer lumber) is revolutionizing the door and construction industry. This article delves into the world of LVL, specifically its use in door cores, exploring the benefits, applications, and why it's becoming a preferred choice for builders and manufacturers. Whether you're a construction company, a door manufacturer, or a building material supplier, understanding the power of LVL is crucial. Learn why LVL offers superior strength, stability, and versatility, making it an excellent product for various construction needs.

What is LVL and Why Use it for Door Cores?

LVL stands for laminated veneer lumber, an engineered wood product created by bonding thin veneer layers together using adhesive. This wood product is a versatile alternative to solid wood, offering high strength and dimensional stability. It's commonly used in applications such as door cores, headers, beams, and other structural components. The door core is the internal structure of the door, providing strength, stability, and insulation.

Using LVL for door cores is a smart choice. The laminate construction ensures consistent strength and prevents warping, which can be a problem with solid wood. Unlike traditional materials, LVL provides a stable and reliable foundation for doors, ensuring longevity and performance.

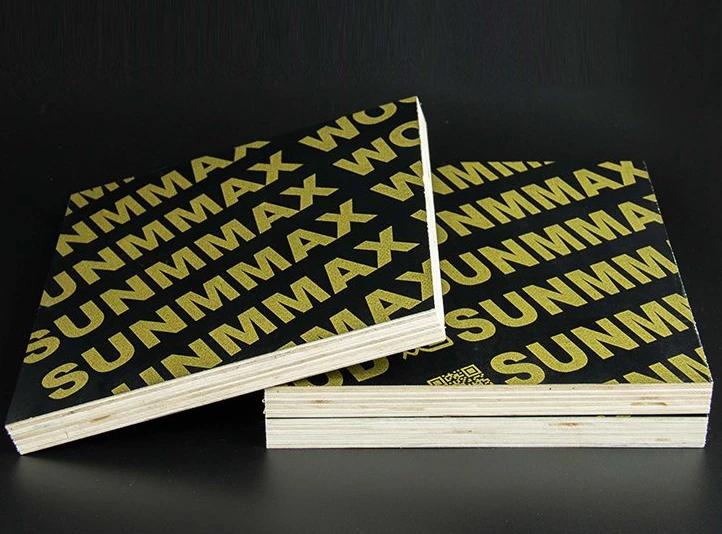

Here is an example of a film faced plywood product.

Advantages of LVL Door Cores Over Traditional Materials

Compared to solid wood, LVL boasts several key advantages. It's less prone to warping, shrinking, or expanding with changes in humidity, which can affect door performance and appearance. The strength to weight ratio of LVL is another significant benefit.

Here's a breakdown:

- Dimensional Stability: LVL maintains its shape and size, ensuring the door fits properly and functions smoothly over time.

- High Strength: LVL offers superior strength compared to solid wood, making doors more durable and resistant to damage.

- Consistency: LVL provides consistent quality and performance, unlike natural wood, which can vary from piece to piece.

- Warp Resistance: LVL is engineered to resist warping, ensuring the door remains flat and functions correctly.

- Versatile: LVL can be used for door frame, jamb, and other structural components, providing great flexibility in construction.

Poplar LVL: A Top Choice for Door Cores

Poplar is a frequently used wood species for LVL door cores due to its excellent properties. The poplar lvl for door core offers a good balance of strength, weight, and workability. It is cost-effective and readily available, making it a popular choice among manufacturers. This makes poplar LVL ideal for the core of the door.

In addition to poplar, other wood species can also be used in the manufacturing of LVL, each providing different characteristics suited to the specific door requirements. Depending on the desired strength and the intended application of the door, the selection of a poplar or a mix of poplar lumber might be necessary.

Here is an example of poplar LVL product.

Applications of LVL Beyond Door Cores: A Versatile Product

While door cores are a primary application, LVL’s versatility extends far beyond. LVL serves as a versatile alternative in various construction projects. It can be used in headers, beams, and frames for windows, providing strength and stability.

Here are some other key applications:

- Headers: LVL headers can be used to support the weight above door and window openings, ensuring structural integrity.

- Beams: LVL beams offer a high strength to weight ratio, making them suitable for long spans and heavy load bearing applications.

- Frame: LVL can create a solid, strong frame for a variety of building components, including door frames.

- LVL also finds applications in the manufacturing of furniture, especially in structural components.

Key Features to Consider When Selecting LVL for Door Cores

When choosing LVL for door cores, several features are worth considering:

- Thickness: LVL comes in various thicknesses, the choice depends on the door design and required strength.

- Size: Standard sizes are available, but custom sizes can be created to meet specific project requirements.

- Strength Grade: LVL is graded based on its strength properties, so it's crucial to choose the right grade for the intended application. E14 LVL provides a reliable solution for a variety of structural needs.

- Moisture Content: Ensure the LVL has an appropriate moisture content to prevent warping or shrinkage.

- Adhesive: The adhesive used in LVL manufacturing should be durable, water-resistant, and meet relevant standards.

The LVL Manufacturing Process: Ensuring Quality and Consistency

The manufacturing process of LVL is complex and ensures high-quality lumber. It involves several steps:

- Veneer Preparation: Thin wood veneers are cut from logs and dried to a precise moisture content.

- Adhesive Application: A durable adhesive is applied to the veneers.

- Layering: The veneers are layered with the grain running in the same direction.

- Pressing: The layers are pressed together under high pressure and temperature to form a solid beam or panel.

- Cutting and Finishing: The LVL is cut to the required size and finished.

The precision in these steps guarantees that the final product has the desired strength, stability, and dimensional accuracy.

LVL and Sustainability: Environmentally Conscious Construction

Sustainability is a growing concern in the construction industry, and LVL offers some environmentally friendly options. Several manufacturers use wood from sustainably managed forests, and some products are certified by organizations like the Forest Stewardship Council (FSC). Utilizing LVL in place of traditional solid wood can also help conserve wood resources.

Using sustainably sourced LVL helps reduce your environmental footprint, making it a popular choice among architects and builders focused on eco-friendly projects. Additionally, LVL is capable of providing protection against insects and other pests.

Here is an example of a floor product.

LVL Lumber Prices and Cost-Effectiveness

The price of LVL can vary based on several factors:

- Wood Species: Poplar is often more cost-effective compared to certain other species.

- Thickness and Size: Larger dimensions typically cost more.

- Grade: Higher strength grades command a higher price.

- Quantity: Bulk orders usually qualify for lower per-unit costs.

However, the long-term benefits and durability of LVL often make it a cost-effective choice. Considering the reduced waste, labor savings, and the strength advantages, LVL can be a sound investment. The cost of LVL beams, lvl lumber prices, and lvl plank depend on a variety of factors, including thickness, width, and length. The use of LVL also contributes to improved project timelines.

Customization Options for LVL Door Cores

LVL offers numerous customization options to meet specific project requirements.

- Size: LVL can be cut to almost any size, providing design flexibility.

- Thickness: Various thicknesses are available, allowing for different door designs.

- Surface Finishes: Surfaces can be treated with paints, stains, or veneers to match the door design.

- Core Design: LVL cores can be designed with different densities or voids for specific performance characteristics, such as enhanced sound insulation.

These customization features make LVL a versatile material for a wide range of door styles and applications.

The Future of LVL in the Construction Industry

LVL is poised to play an even larger role in the future of the construction industry. As builders and designers seek sustainable, high strength, and cost-effective materials, the demand for LVL will continue to grow.

New advancements in adhesive technology, manufacturing processes, and wood species are constantly improving the performance and versatility of LVL. It is already widely used for LVL framing and increasingly adopted in other applications, such as I-joists and OSB panel applications and lvl scaffolding plank..

LVL is expected to be increasingly used to replace traditional solid wood in a wide range of applications, from doors and windows to structural components and furniture. As building codes and standards evolve, LVL will continue to adapt and meet the growing demands of the construction industry.

-

Summary of Key Takeaways

- LVL is an engineer wood product that provides superior strength, stability, and warp resistance compared to traditional materials, making it an excellent choice for door cores.

- Poplar LVL is a popular and cost-effective option for door cores due to its good balance of properties.

- LVL offers a wide range of applications beyond door cores, including headers, beams, and window frames, and is a versatile alternative to traditional building materials.

- When selecting LVL, consider thickness, strength grade, and moisture content to ensure it meets the project's requirements.

- The sustainable sourcing and environmental benefits of LVL are becoming increasingly important in construction.

- LVL provides excellent opportunities for customization, including size, thickness, and surface treatments, to meet specific design needs.

- The future of LVL in the construction industry looks promising, with growing demand and ongoing advancements in manufacturing and technology.

-

Benefits of Choosing LVL

- Dimensional stability: LVL maintains its shape and size, ensuring a perfect fit.

- High strength: LVL offers superior strength compared to solid wood.

- Resistance to warping: LVL is engineered to resist warping, ensuring your door functions correctly.

- Versatility: LVL can be used for door frame, jamb, and other components.

Ready to explore how LVL can enhance your next project? Contact us to discuss your needs and discover the benefits of high-quality engineered wood products. We offer a range of LVL options, including those that meet the strength and safety standards you are looking for.

Post time: Feb-18-2025