Choosing the right material for your project, whether it's building cabinets, shelves, or tackling a larger construction endeavor, can be tricky. This article dives deep into the difference between MDF and plywood, two popular wood composite materials. We'll break down their composition, strengths, weaknesses, and ideal applications, helping you make an informed decision. Understanding the nuances of plywood, fiberboard, and even particle board is crucial for achieving quality and longevity in your work. So, if you're wondering about mdf vs plywood and want a clear difference and comparison, keep reading – this guide is for you!

1. What is Plywood and How is it Made? Understanding the Layers of Wood Veneer.

Plywood is a versatile engineered wood product crafted from three or more thin sheets of wood, called wood veneer or ply, glued together. These thin layers are oriented with their wood grain running at right angles to each other. This cross-graining process is what gives plywood its exceptional strength and stability. Imagine stacking layers of paper – they're easy to bend. But if you alternate the direction of the fibers in each layer, it becomes much stronger and resistant to bending or warping. That's the basic principle behind plywood is made.

The manufacturing process involves peeling logs into thin sheets of wood veneer. These sheets of wood veneer are then dried, graded, and coated with adhesive. The layers are then assembled with alternating grain directions and subjected to intense heat and pressure, bonding them permanently. The type of adhesive used can vary, and for applications where formaldehyde emissions are a concern, formaldehyde-free plywood is available. This construction makes plywood a robust building material widely used in construction.

2. What is MDF (Medium Density Fiberboard) and How Does it Differ from Plywood in Composition?

Medium-density fiberboard, or MDF, is another type of engineered wood. However, unlike plywood is made from thin layers of real wood, MDF is created by breaking down hardwood or softwood residuals into fine wood fibers. These wood fibers are then combined with resin and subjected to high heat and pressure to form panels. Think of it like making paper, but with wood fibers instead of plant fibers, resulting in a dense, smooth surface wood product.

The key difference between mdf and plywood lies in their core composition. Plywood retains the distinct layers of wood veneer, while MDF has a consistent density throughout, made of finely processed wood fibers. This gives MDF a very uniform texture and makes it ideal for intricate machining and painting. While both are engineered wood, their manufacturing processes and resulting properties are quite distinct.

3. Plywood vs MDF: What are the Key Difference and Comparison Points to Consider?

When comparing mdf and plywood, several key factors come into play. Plywood generally offers superior strength and durability due to its layered construction. It's better at holding screws very well and can withstand more weight without sagging. Plywood also tends to be more resistant to moisture, although prolonged exposure can still cause damage.

MDF, on the other hand, has a very smooth surface that is excellent for painting. It also machines and cuts cleanly, making it suitable for intricate designs. However, mdf tends to soak up water more readily than plywood, leading to swelling and damage. MDF weighs heavier than plywood for the same thickness. Another significant difference and comparison point is the edge profile. Plywood edges reveal its layered construction, which can be aesthetically pleasing or require edge banding. MDF edges are smooth and uniform. Considering these key differences is crucial when choosing between mdf and plywood.

4. Which is Stronger and More Durable: Plywood or MDF Fiberboard? Examining Strength and Durability.

In terms of pure strength and durability, plywood is stronger than mdf. The cross-grained layers in plywood offer significant resistance to bending and breaking. This makes it a preferred choice for structural applications where load-bearing capacity is essential. Think of subfloors, roof sheathing, and even some furniture frames – these often rely on the inherent strength of plywood.

While MDF is dense and stable, it's more prone to denting and damage from impacts. MDF doesn’t hold screws as securely as plywood, especially with repeated use. When it comes to moisture resistance, plywood generally performs better. While neither material is entirely waterproof, mdf tends to soak up water much more quickly, leading to swelling and disintegration. Therefore, for projects exposed to humidity or potential moisture, plywood is generally the better choice. The strength of plywood makes it a long-lasting building material.

5. What are the Different Types of Plywood Available, and When Should You Use Each?

There isn't just one type of plywood; there are various types of plywood designed for specific applications. Hardwood plywood features a hardwood face veneer and is often used for high-end furniture, cabinetry, and interior paneling where aesthetics are important. Softwood plywood, typically made from pine or fir, is commonly used in construction for sheathing, flooring underlayment, and roofing.

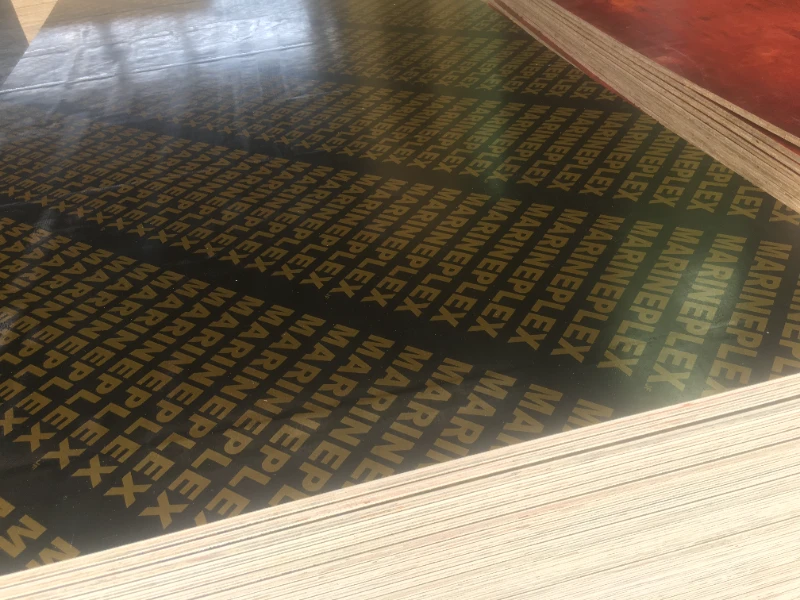

Marine plywood is a high-grade plywood made with waterproof adhesive and is designed for use in boat building and other marine applications. Film faced plywood, like the phenolic film faced plywood 16mm, has a durable resin coating that makes it ideal for concrete formwork and other applications requiring a smooth, reusable surface. Structural plywood, like our 18mm structural ply, is engineered to meet specific load-bearing requirements in construction. Understanding these different plywood grades helps in selecting the one for your project. We also offer non structural plywood for applications where high strength isn't required.

6. When is MDF a Better Choice Than Plywood? Exploring Suitable Applications.

Despite its limitations in strength and moisture resistance, MDF has several advantages that make it the better choice for certain projects. Its extremely smooth surface is ideal for painting, as it doesn't have the wood grain of plywood that can show through paint. This makes it a popular choice for painted cabinet doors, furniture parts, and decorative moldings.

MDF's uniform density allows for clean and precise cuts, making it excellent for intricate designs and routing. It's also generally cheaper than plywood, which can be a significant factor for budget-conscious projects. You might find mdf commonly used in ready-to-assemble furniture, speaker boxes, and interior trim where structural integrity isn't the primary concern. When the priority is a perfectly smooth painted finish and intricate detailing, using mdf can be the right decision.

7. When Should You Use Plywood? Highlighting its Best Uses in Construction and Furniture.

Plywood excels in applications where strength and stability are paramount. In construction, it's a workhorse material used for subflooring, wall and roof sheathing, and concrete formwork. Its ability to withstand loads and resist warping makes it essential for building sturdy structures.

In furniture making, plywood can be used for cabinet boxes, drawer bottoms, and chair frames, providing a solid foundation. Hardwood plywood with attractive veneers is often used for exposed surfaces where aesthetics matter. Due to its relative moisture resistance compared to MDF, plywood is also a better choice for projects in bathrooms, kitchens, or outdoor applications (though treated or higher grades of plywood are recommended for prolonged outdoor exposure). If you need a material that can hold screws very well and withstand some wear and tear, use plywood.

8. MDF vs Plywood for Cabinets and Shelves: Which Material Shines?

The choice between mdf or plywood for cabinets and shelve depends largely on the specific application and desired finish. For cabinet boxes and shelves that will bear significant weight, plywood is generally the preferred choice due to its superior strength and durability. Plywood holds screws better, ensuring the structural integrity of the cabinet over time.

However, for painted cabinet doors and drawer fronts, MDF can be an excellent option. Its smooth surface provides a flawless base for paint, resulting in a professional-looking finish. For shelve, if the load is light and a painted finish is desired, MDF can be suitable. Ultimately, many cabinet makers use a combination of both materials, employing plywood for the structural components and MDF for the painted elements.

9. What is the Cost of Plywood Compared to MDF and Other Wood Composite Options like Particle Board?

Generally, plywood is more expensive than MDF. The manufacturing process for plywood, involving multiple layers of wood veneer and careful adhesion, is more complex than that of MDF. The type of plywood also affects its cost, with hardwood plywood and specialty plywood like marine-grade being more expensive than regular softwood plywood.

MDF is a more budget-friendly option due to its simpler manufacturing process using wood residuals. Particle board, another wood composite made from wood chips and resin, is typically the cheapest option among the three. However, particle board is the least strong and durable, making it suitable only for light-duty applications. While cost is a factor, it's crucial to balance it with the required performance characteristics when choosing between mdf and plywood.

10. Making the Right Choice: Considering Your Project Needs and Whether to Use Plywood or MDF.

The choice between mdf and plywood boils down to understanding the specific requirements of your project. If strength and durability are paramount, and the project may be exposed to moisture or heavy loads, plywood is the clear winner. It's a robust material that will stand the test of time.

If you need a perfectly smooth surface for painting intricate designs, and the project won't be subjected to heavy loads or moisture, MDF offers an excellent and often more cost-effective solution. Consider the finish, the structural demands, and the environment where the finished product will reside. Sometimes, a combination of both materials, like using plywood for the structure and MDF for the faces, offers the best of both worlds. By carefully considering these factors, you can confidently choose the one for your project. Remember, we offer a range of high-quality plywood, including structural options and film faced ply 15mm, and other engineered wood products to meet your specific needs. For structural applications, consider our LVL Timber (Engineered Wood Products).

Key Things to Remember:

- Plywood is stronger and more durable than MDF due to its layered construction.

- MDF has a smoother surface, making it ideal for painting.

- Plywood is generally more resistant to moisture than MDF.

- MDF is typically cheaper than plywood.

- Consider the specific requirements of your project – strength, finish, and environment – when choosing between the two.

- Particle board is the least expensive but also the least durable option.

- Both MDF and plywood are versatile engineered wood products with unique strengths.

Post time: Jan-14-2025