This article dives deep into the common problem of warped plywood, a frustrating issue for anyone working with wood. Whether you're a professional builder like Mark Thompson from the USA, sourcing materials from China, or a DIY enthusiast, understanding how to prevent and fix plywood warping is crucial. This guide will equip you with practical techniques, expert insights (from a factory perspective, like my own, Allen's, in China), and preventative measures to ensure your projects stay flat, true, and structurally sound. We focus primarily on the needs of B2B customers – construction companies, material suppliers, and manufacturers who rely on consistent quality.

Understanding Plywood Warping: Causes and Prevention

What Causes Plywood to Warp?

Warp in plywood is primarily caused by changes in moisture content. Plywood is made of thin layers of wood (veneer) glued together. When these layers of wood absorb or release moisture unevenly, internal stresses develop, causing the plywood to bend, twist, or cup. This phenomenon, known as wood warping, is particularly problematic in environments with fluctuating humidity. My factory, specializing in engineered wood products, sees this as a major concern for our clients in North America and Europe.

Think of it like this: if one side of a 4 x 8 sheet of plywood absorbs more moisture than the other, it expands more, forcing the entire sheet to curve. This is why wood changes unevenly. Even minor differences in the grain direction between plies can exacerbate this issue.

How Does Moisture Content Affect Plywood Stability?

The moisture content of plywood is the percentage of water weight relative to the dry weight of the wood. Ideal moisture content for most interior applications is between 6% and 8%. Higher levels, common in humid environments or during shipping from countries like China, can lead to significant warp. This is one of Mark Thompson's key concerns, and rightfully so. Delays due to warped plywood can seriously impact construction schedules.

As a supplier, we understand that controlling moisture during production and shipping is critical. This involves using properly dried veneer, appropriate glue, and careful packaging to minimize moisture absorption during transit to destinations like the USA and Australia.

Practical Techniques for Straightening Warped Plywood

Can You Really Fix Warped Plywood?

Yes, in many cases, you can straighten warped plywood. However, the success rate depends on the severity of the warp and the type of plywood. Minor warping is usually easier to correct than severe twisting or cupping. Note that with significant warp, complete flattening may compromise the structural integrity of the plywood.

The Wetting and Weighting Method: A Step-by-Step Guide

This is a common method, especially effective for thinner plywood.

- Assess the Warp: Determine the direction of the warp (convex or concave).

- Thoroughly Wet the concave side of the plywood. You can use a spray bottle, damp cloth, or even a garden hose. The goal is to saturate the wood fibers on that side.

- Apply Weight: Place the plywood, wet side down, on a flat surface. Distribute heavy, even weight across the entire sheet. Think concrete blocks, stacks of books, or even sandbags.

- Monitor and Adjust: Check the plywood every few hours. As the wet side expands and the dry side contracts, the plywood should gradually straighten. You may need to re-wet the concave side several times.

- Drying Time: Allow the plywood to dry completely under weight. This can take several days, depending on the thickness of the plywood and the ambient humidity.

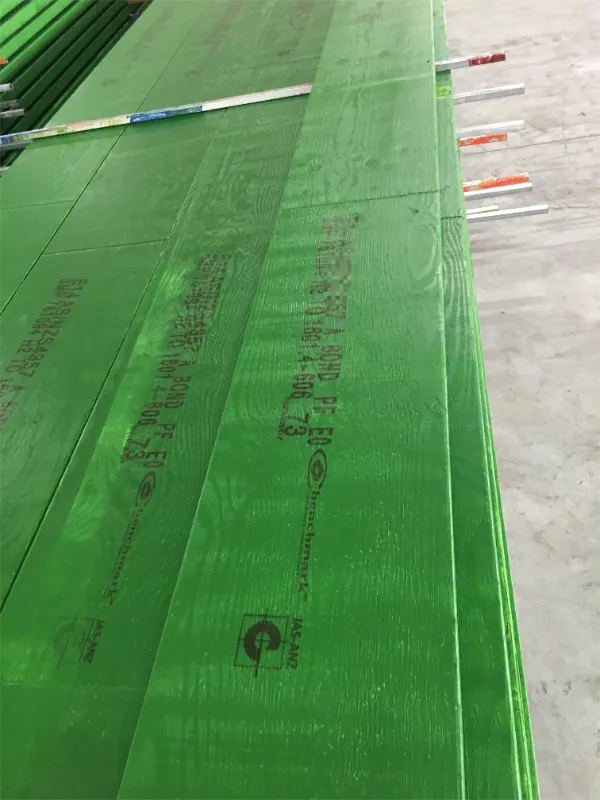

This image shows an example of the weighting technique,

Using Clamps and a Stiff Backer Board: A More Controlled Approach

For more stubborn warps, especially in thicker plywood like structural ply, this method offers more control.

- Prepare the Backer: Find a strong, flat, and rigid backer board, such as a thick piece of MDF or a steel square tubing frame.

- Wet the Plywood: Thoroughly wet the concave side, as described above.

- Clamp the Plywood: Position the warped plywood on the backer board, with the concave side facing up. Use clamps to gradually pull the warped areas down towards the backer board. Start with gentle pressure and increase it gradually.

- Monitor and Adjust: Regularly check the progress and adjust the clamps as needed.

- Drying Time: Allow the plywood to dry completely while clamped. This may take several days.

Can Heat Be Used to Straighten Warped Plywood?

While heat can accelerate the process, it also carries risks. Excessive heat can damage the glue and weaken the plywood. If using heat, apply it gently and evenly, using a heat gun on a low setting or placing the plywood in direct sunlight. Always monitor the plywood closely to prevent overheating. This is not a recommended method for film faced plywood, as the heat can damage the surface finish.

What About Using Steam to Straighten Warped Plywood?

Steam can be effective, but it's a more advanced technique. It involves applying steam to the concave side of the plywood, making the wood fibers more pliable. This requires specialized equipment and careful control to avoid over-saturation and potential damage. It's generally best left to experienced professionals.

Preventing Plywood Warp: Best Practices for Storage and Handling

How Should Plywood Be Stored to Prevent Warping?

Proper storage is paramount. Here are key recommendations, directly relevant to companies importing from overseas, like Mark Thompson's:

- Flat and Supported: Store plywood horizontally on a flat, level surface. Avoid leaning it against a wall, which can induce warp. Use stickers (2x4s or similar) to elevate the stack and allow for air circulation.

- Controlled Environment: Maintain a stable temperature and humidity. Avoid extreme fluctuations, which can cause the wood to expand and contract rapidly. Ideal storage conditions are around 70°F (21°C) and 35-50% relative humidity.

- Covered Storage: Protect the plywood from direct sunlight and moisture. If storing outdoors, use a waterproof tarp, ensuring adequate ventilation to prevent moisture buildup.

- Acclimation: Before using the plywood, allow it to acclimate to the environment where it will be installed. This helps minimize dimensional changes after installation. This is especially important for products like flooring. Solid wood flooring is very susceptible to moisture related warping.

What Precautions Should Be Taken During Transportation?

- Secure Packaging: Ensure the plywood is securely packaged and protected from moisture during shipping. This is especially critical for long sea voyages from China. We, at Jsylvl, take extra precautions for our export shipments to minimize the risk of moisture damage.

- Proper Handling: Use forklifts with appropriate forks to avoid damaging the edges of the plywood sheets.

- Avoid Extreme Temperatures: Protect the plywood from extreme temperatures during transit.

What Role Does Plywood Grade Play in Warping Resistance?

The grade of plywood significantly impacts its resistance to warp. Higher-grade plywood, like structural plywood (e.g., F17 grade, commonly used in Australia), is typically made with higher-quality veneers and stronger glue, making it more stable and less prone to warp. For example, Formply F17 1800×1200×17mm is built to handle the harsh environment of concrete forms. Non-structural plywood, while suitable for some applications, is generally more susceptible to warping.

Are There Specific Types of Plywood Less Prone to Warping?

- Marine Plywood: Designed for high-moisture environments, marine plywood is made with waterproof glue and high-quality veneers, offering excellent warp resistance. Check out the offering from JSYLVL: marine plywood.

- LVL (Laminated Veneer Lumber): LVL is an engineered wood product consisting of multiple layers of thin veneer bonded together with strong adhesives. Its layered construction and consistent density make it highly resistant to warp. A common product from JSYLVL is: laminated veneer lumber LVL beams E13.2.

- Film Faced Plywood: While the core material can still warp, the film facing provides a barrier against moisture absorption, reducing the likelihood of warping.

- Baltic Birch Plywood: It is high quality plywood and known for its stability and resistance to warping.

Addressing Common Customer Concerns: A Supplier's Perspective

How Do I Verify the Quality of Plywood to Minimize Warping Issues?

From my experience (Allen, from the Jsylvl factory), transparency and verifiable quality control are key. Reputable suppliers should readily provide:

- Grading Certificates: These documents confirm the plywood meets specific standards for strength, veneer quality, and glue bond.

- Moisture Content Readings: Request documentation of the moisture content of the plywood at the time of shipment.

- Factory Audits: For large-volume buyers, consider requesting a factory audit to assess production processes and quality control measures.

- Samples: Always request samples before placing a large order. This allows you to inspect the plywood for flatness, veneer quality, and overall construction.

What Certifications Should I Look For?

- FSC (Forest Stewardship Council): Ensures the wood comes from responsibly managed forests.

- CARB (California Air Resources Board): Compliance with CARB regulations indicates low formaldehyde emissions, important for indoor air quality.

- Structural Certifications: Relevant certifications (e.g., AS/NZS 2269 for Australia) ensure the plywood meets structural performance requirements.

What Are the Typical Lead Times and Logistics for Plywood Shipments from China?

Lead times can vary depending on the order size, plywood type, and current production schedules. Generally, expect lead times of 4-8 weeks from order confirmation to shipment. Logistics typically involve sea freight, with transit times ranging from 2-4 weeks to North America and 3-5 weeks to Europe. Working with a supplier experienced in international shipping is crucial to ensure smooth customs clearance and timely delivery.

What Payment Methods Are Typically Accepted by Chinese Plywood Suppliers?

Common payment methods include:

- Letter of Credit (L/C): A secure payment method often used for large international transactions.

- Telegraphic Transfer (T/T): A wire transfer of funds, typically with a portion paid upfront and the balance upon shipment.

- Documentary Collection (D/P or D/A): Payment against documents, offering a balance of risk for both buyer and seller.

Plywood Warping and Specific Applications

Formwork and Warped Plywood: A Critical Issue

In formwork, plywood flatness is absolutely critical. Warped formply can lead to uneven concrete surfaces, requiring costly rework. Using high-quality formply, like F17 grade, and ensuring proper storage and handling are essential to prevent this.

Flooring and Warped Plywood Subfloors

A warped subfloor will telegraph through to the finished flooring, creating an uneven and unsightly surface. Using stable subfloor materials, like OSB or structural plywood, and allowing for proper acclimation are crucial for a successful flooring installation.

Furniture Manufacturing and the Importance of Stable Plywood

Furniture makers demand high-quality, stable plywood to ensure the structural integrity and aesthetic appeal of their products. Warped plywood can lead to misaligned joints, uneven surfaces, and overall poor quality.

Key Takeaways: Preventing and Fixing Warped Plywood

- Moisture Content is King: The primary cause of plywood warping is uneven moisture absorption.

- Prevention is Better Than Cure: Proper storage, handling, and acclimation are crucial for preventing warp.

- Choose the Right Grade: Select the appropriate grade of plywood for your application, considering its warp resistance.

- Wetting and Weighting: A common and effective method for straightening minor warps.

- Clamps and Backer Boards: For more stubborn warps, use clamps and a rigid backer board for controlled straightening.

- Heat and Steam with Caution: These methods can be effective but require experience and careful control.

- Partner with Reputable Suppliers: Choose suppliers who prioritize quality control and provide verifiable documentation.

- Understand Lead Times and Logistics: Be aware of typical lead times and logistics when sourcing plywood internationally.

- Always Inspect Before Use: No matter where you buy plywood, always inspect it.

By following these guidelines, builders, manufacturers, and suppliers can minimize the challenges posed by warped plywood, ensuring successful projects and satisfied customers. Remember, consistent quality and proactive measures are the keys to avoiding costly rework and delays.

Post time: Mar-03-2025