Navigating the world of plywood can feel like deciphering a complex code. From construction sites to crafting workshops, plywood is a versatile and essential material. This comprehensive guide breaks down the different types of plywood, explaining their unique characteristics and ideal applications. Whether you're a construction professional or a DIY enthusiast, understanding the nuances of plywood type is crucial for successful projects. Dive in to discover everything you need to know about choosing the right plywood.

1. What Exactly is Plywood and Why is it So Widely Used?

Plywood is a sheet material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. This cross-graining imparts exceptional strength and stability, making plywood is generally stronger than solid wood of the same dimensions and less prone to warping or splitting. This innovative construction is why plywood is often used in a vast array of applications, from building construction and furniture making to packaging and even aircraft construction. As Allen from JSYLVL in China, a leading factory specializing in engineered wood products, can attest, the versatility and reliability of plywood make it an indispensable material in the modern world. Our multiple production lines ensure we can meet the diverse demands of our B2B customers in the USA, North America, Europe, and Australia.

2. Exploring the Two Main Categories: Softwood Plywood vs. Hardwood Plywood - What's the Difference?

The primary distinction between softwood plywood and hardwood plywood lies in the type of wood used to create the veneer layers. Softwood plywood is generally made from coniferous trees like pine, fir, and spruce. These trees grow relatively quickly, making softwood plywood a more economical option for many construction projects, such as sheathing, roofing, and subflooring. Hardwood plywood, on the other hand, hardwood plywood is made from deciduous trees like oak, birch, maple, and poplar. These woods are denser and offer a smoother surface, making hardwood plywood ideal for applications where aesthetics and durability are paramount, such as furniture making, cabinetry, and interior paneling. At JSYLVL, we offer a wide range of both softwood plywood and hardwood plywood options to cater to the specific needs of our clients, ensuring they have access to the right plywood for their intended purpose. For instance, birch plywood is a popular choice for furniture due to its strength and smooth finish.

3. Understanding Plywood Grades: What Do the Letters Mean (A, B, C, D)?

When selecting plywood, understanding the grading system is crucial. Plywood is graded based on the quality and appearance of the veneer on the face and back of the plywood panels. The most common system uses letters: A, B, C, and D.

- A-Grade Plywood: This is the highest grade of plywood, featuring a smooth, sanded surface that is free from knots and repairs. It's ideal for applications where a flawless finish is required and is often used for high-end furniture making or cabinet doors.

- B-Grade Plywood: While still smooth and sandable, b-grade plywood may have a few minor knots or repairs. It's a good choice for projects where appearance is important but doesn't need to be perfect.

- C-Grade Plywood: This grade plywood allows for tight knots (up to a certain size) and some discoloration. It's typically used for applications where appearance is less critical, such as underlayment or crating.

- D-Grade Plywood: The lowest grade of plywood, c-grade plywood can have large, open knots and defects. It's primarily used for structural applications where appearance is not a concern and is often used for exterior sheathing plywood.

It's important to note that plywood is usually graded with two letters, one for each face (e.g., AC, BC, CD). This indicates the grade of plywood on both sides of the sheet. As a factory, JSYLVL ensures strict quality control to meet the specified plywood grade requirements for our customers.

4. What are the Common Types of Plywood and Their Ideal Uses?

The world of plywood encompasses many types, each tailored for specific applications. Here are some common types of plywood:

-

Construction Plywood: Often a softwood plywood, this is the workhorse of the building industry. It's used for wall and roof sheathing, subflooring, and general construction projects. Our structural ply, available at https://www.jsylvl.com/structural-ply/, is a testament to our commitment to providing high-quality materials for this purpose.

-

Hardwood Plywood: Prized for its smooth surface and aesthetic appeal, hardwood plywood is ideal for furniture, cabinetry, interior paneling, and decorative applications.

-

Marine Plywood: Designed for use in wet environments, marine plywood is manufactured with waterproof glue and is typically made from durable hardwood veneer. While not entirely waterproof, it's highly water-resistant and marine plywood is designed to withstand prolonged exposure to moisture. It's commonly used in boat building and dock construction. You can learn more about our marine plywood options here: https://www.jsylvl.com/marine-plywood/.

-

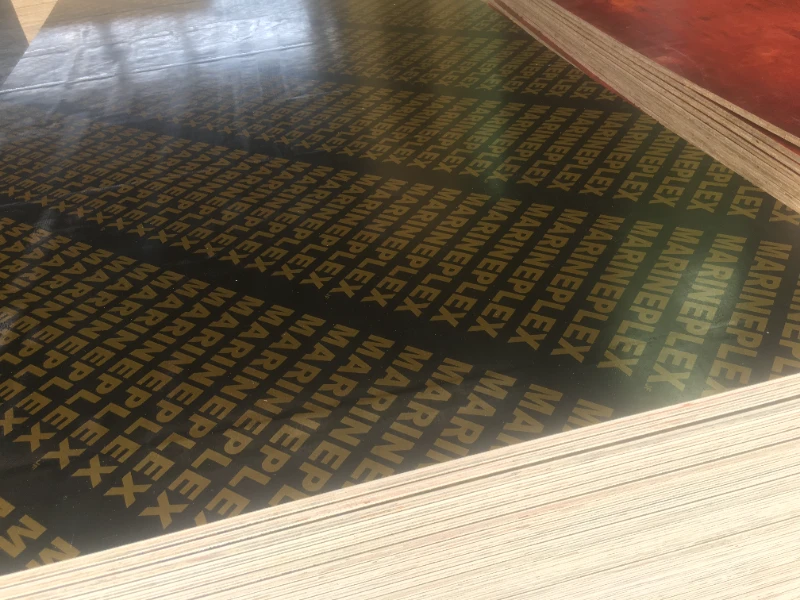

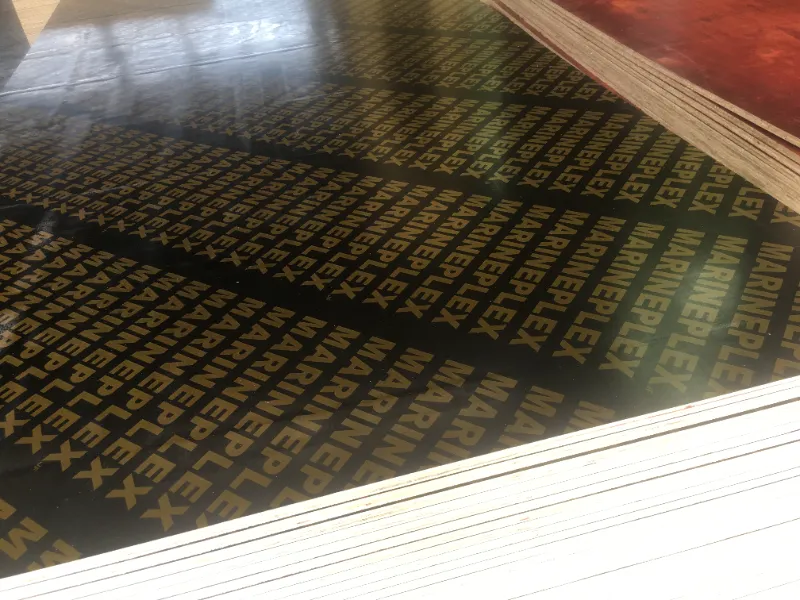

Film Faced Plywood: This type of plywood has a special coating of phenolic resin film on its surface, making it highly durable and resistant to moisture, abrasion, and fungal attack. Film faced plywood is often used in concrete formwork due to its ability to create smooth concrete surfaces and withstand repeated use. Explore our film faced plywood range: https://www.jsylvl.com/12mm-film-faced-plywood/.

-

Overlay Plywood: Similar to film-faced, but the overlay can be paintable or stainable, providing a smooth surface for finishing.

-

Flexible Plywood: Also known as bendy board or wiggle board, flexible plywood is designed to bend easily, making it suitable for curved surfaces and architectural details.

-

Aircraft Plywood: A high-strength hardwood plywood, aircraft plywood is manufactured to strict specifications for use in aircraft construction. It uses thin veneer layers and high-quality adhesives to achieve its strength-to-weight ratio.

5. Diving Deeper: What Makes Structural Plywood Different and When Should You Use It?

Structural plywood is designed for applications where strength and load-bearing capacity are critical. This type of plywood adheres to specific building codes and standards, ensuring it meets the required performance criteria for structural integrity. Key plywood features of structural plywood include specific wood species, adhesive types, and manufacturing processes that enhance its strength and stiffness. Structural plywood is essential for framing walls, floors, and roofs, providing the necessary support and stability for buildings. When choosing plywood for structural purposes, it's crucial to select the correct plywood ratings and ensure it complies with local building regulations. At JSYLVL, our structural plywood, such as our 18mm structural ply (https://www.jsylvl.com/18mm-structural-ply/), is rigorously tested to meet the demanding requirements of the construction industry.

6. Marine Plywood: Is it Really Waterproof and When is it the Best Choice?

While often referred to as waterproof plywood, marine plywood is more accurately described as highly water-resistant. The key to its moisture resistance lies in the waterproof adhesives used to bond the veneer layers. Furthermore, marine plywood is typically made from durable hardwood species that are naturally resistant to decay. Marine plywood is designed for demanding applications where exposure to water is inevitable, such as boat building, docks, and outdoor furniture. It's important to note that even marine plywood can be damaged by prolonged submersion, so proper sealing and maintenance are still recommended. When your project demands superior resistance to moisture, marine plywood is the best plywood choice.

7. What About Specialty Plywood? Exploring Unique Types of Ply for Specific Needs.

Beyond the common types, there's a world of specialty plywood designed for niche applications. These types of ply often incorporate unique materials or manufacturing processes to achieve specific properties. Examples of specialty plywood include:

- Aircraft Plywood: As mentioned earlier, this high-grade hardwood plywood meets stringent requirements for aviation use.

- Lumber Core Plywood: This plywood features a core made of solid wood lumber, sandwiched between veneer layers. It offers excellent screw-holding ability and is often used in furniture making.

- MDF Core Plywood: This plywood uses a medium-density fiberboard (MDF) core, providing a very smooth and stable surface, ideal for painting.

- Baltic Birch Plywood: Known for its void-free core and superior strength, baltic birch plywood is a premium hardwood plywood favored by woodworkers and cabinet makers.

-

Concrete Formwork Plywood (Formply): Often synonymous with film faced plywood, this type is specifically designed for creating molds for concrete structures. Our Formply, including options like https://www.jsylvl.com/formply-f17-2400x1200x17mm/, demonstrates our expertise in this area.

8. Plywood Thickness and Sizes: What Options are Available and How Do You Choose the Right One?

Plywood comes in a variety of thicknesses and standard sheet sizes. Common plywood thickness options range from thin 1/8-inch sheets to thicker options exceeding 1 inch. The appropriate plywood thickness depends on the intended application and the structural requirements of the project. For example, thin plywood might be used for drawer bottoms or decorative overlays, while thicker plywood is necessary for subflooring or load-bearing walls. Standard plywood sizes are typically 4x8 feet, but other sizes, such as 4x10 or 5x5 feet, may also be available. When selecting plywood, consider the dimensions required for your project to minimize waste and ensure proper fit.

9. Considering Plywood Alternatives: When Might Another Material Be a Better Fit?

While plywood offers a compelling combination of strength, stability, and versatility, there are situations where plywood alternatives might be more suitable. For instance, oriented strand board (OSB) is often used as a cost-effective alternative to sheathing plywood in construction. Medium-density fiberboard (MDF) provides a smoother surface than plywood and is often used for painted cabinet doors. For applications requiring high moisture resistance but less structural strength, materials like PVC boards might be considered. However, for many structural and aesthetic applications, plywood its strength and layered construction remain unmatched.

10. Choosing the Right Plywood for Your Project: Key Factors to Consider.

Selecting the right plywood type is crucial for the success of any project. Consider these key factors when making your decision:

- Application: What will the plywood be used for? (e.g., structural framing, furniture, exterior siding)

- Strength Requirements: Does the project require high load-bearing capacity? If so, structural plywood is essential.

- Moisture Exposure: Will the plywood be exposed to water or humidity? Marine plywood or film faced plywood might be necessary.

- Appearance: Is a smooth, paintable, or stainable surface required? Hardwood plywood or sanded plywood grades (A or B) are good choices.

- Budget: Softwood plywood is generally more economical than hardwood plywood.

- Building Codes: Ensure the chosen plywood meets local building codes and standards, especially for structural applications.

By carefully considering these factors, you can choose plywood that meets your specific needs and ensures the longevity and success of your project. As Allen from JSYLVL, a trusted supplier of high-quality LVL Timber and plywood, including structural plywood and non-structural plywood, can confirm, understanding the different types of plywood is the first step towards making informed purchasing decisions. We cater to B2B clients like Mark Thompson in the USA, who seek cost-effective and reliable engineered wood products. Mark, as a company owner and procurement officer, understands the importance of quality inspection, certifications, and timely logistics – aspects we prioritize at JSYLVL. We aim to alleviate his pain points regarding inconsistent quality and shipment delays. You can explore our diverse range of plywood boards and other engineered wood products on our website.

Key things to remember about different types of plywood:

- Plywood is made of multiple layers of wood veneer glued together for strength.

- The main types of plywood include softwood and hardwood, each with different properties.

- Plywood is graded based on the quality of its face veneer (A, B, C, D).

- Structural plywood is designed for load-bearing applications and meets specific building codes.

- Marine plywood is highly water-resistant but not entirely waterproof.

- Film faced plywood is durable and ideal for concrete formwork.

- Consider the application, strength requirements, moisture exposure, and appearance when choosing the right plywood.

Post time: Jan-08-2025