This comprehensive guide explores the world of film faced plywood, a versatile and durable building material. We'll delve into its composition, benefits, and various applications, focusing on the 18mm thickness, a popular choice for many projects. Whether you're a seasoned construction professional or a DIY enthusiast, this article will provide you with valuable insights to make informed decisions about your next project. Learn why film faced plywood is a superior alternative to other plywood options and how it can enhance the quality and longevity of your builds.

1. What is Film Faced Plywood and Why is it a Great Option?

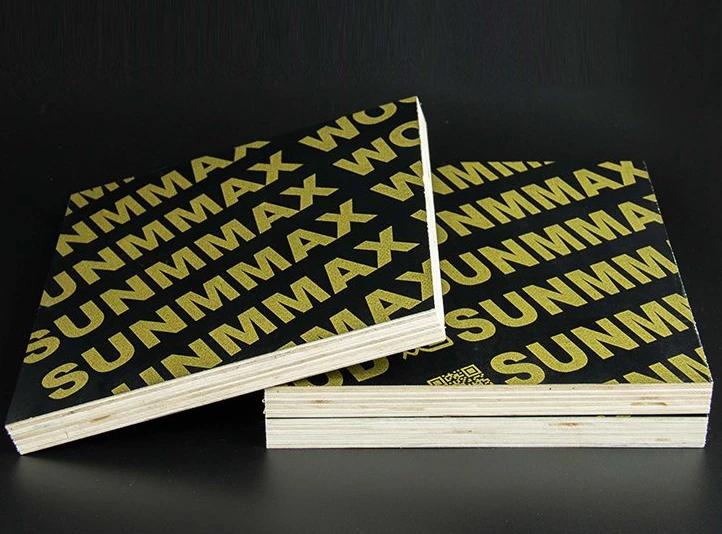

Film faced plywood is a plywood panel with a special coating on both sides. This coating, often a phenolic resin film, provides a waterproof and durable surface, making it ideal for demanding applications. It’s a high-quality plywood covered with resin-treated paper, which then turns into a protective film. This film-faced plywood is engineered to withstand harsh conditions, offering superior performance compared to standard plywood sheets.

It's a popular choice for various construction projects due to its exceptional durability and water resistance. The smooth film surface is also easy to clean and maintain. This characteristic makes it a perfect material for shuttering purposes, where it experiences constant exposure to moisture and concrete.

Plywood offers dimensional stability and strength. It's used in making everything from formwork to furniture, showcasing its versatility.

2. What are the Key Components of Plywood?

Plywood consists of thin layers of wood veneer glued together with the grain of each layer running at a 90-degree angle to the adjacent layer. This cross-graining technique enhances the strength and stability of the plywood, making it less prone to warping and splitting. The core can be made of various wood species, but the faces are typically made from hardwood or softwood, depending on the intended application.

In film faced plywood, the key components include:

- Core: The inner layers of the plywood, which provide the bulk and structural strength. This can be made of various ply layers.

- Veneer: Thin sheets of wood used to construct the layers of the plywood. The quality of the veneer affects the overall strength.

- Adhesive: A strong, waterproof adhesive, often phenolic glue, that binds the veneer layers together.

- Film Coating: The outer layer, which protects the plywood from water, abrasion, and other environmental factors. This is the defining feature of film faced plywood.

3. Is Film Faced Plywood Truly Resistant to Water?

Yes, film faced plywood is highly resistant to water, making it an excellent choice for applications where moisture exposure is a concern. The film coating acts as a barrier, preventing water from penetrating the plywood and causing damage. The edges are sealed to prevent any water ingress, which is an essential feature in guaranteeing its longevity and performance.

The waterproof nature of film faced plywood is one of its most significant advantages. This makes it ideal for outdoor applications, concrete formwork, and areas prone to dampness. Ordinary plywood, without this coating, is susceptible to swelling, warping, and eventual degradation when exposed to moisture.

The special coating makes it highly resistant to water.

4. Why Choose Birch for Your Film Faced Plywood?

Birch is a popular choice for the core of film faced plywood due to its strength, stability, and attractive appearance. Birch plywood offers excellent screw-holding capabilities and a smooth surface, making it ideal for various applications. Moreover, birch is a hardwood, giving the plywood added strength and durability.

Birch film faced plywood combines the advantages of birch plywood with the protective benefits of the film coating. This combination results in a robust and visually appealing product that is suitable for demanding environments. It is a lighter material than birch film.

5. What are the Common Types of Film Faced Plywood?

There are several types of film faced plywood, each designed for specific applications. Some common variations include:

- Phenolic film faced plywood: It offers excellent water resistance and durability. It's a high-quality plywood.

- Anti-slip film faced plywood: This type features a textured surface to provide enhanced grip, making it ideal for flooring in vehicles and scaffolding platforms. It's a popular choice.

- Poplar film faced plywood: This is an alternative option, particularly when seeking a lighter or more cost-effective option. The resulting material can be an excellent choice for formwork.

- Shuttering plywood: Designed specifically for concrete formwork, it provides a smooth surface that facilitates easy concrete release.

The type of plywood selected depends on the intended use and the specific requirements of the project.

6. What are the Benefits of Film Faced Plywood in Construction?

Film faced plywood offers several key benefits of film faced plywood in construction:

- Durability: The film coating provides a protective layer that resists abrasion, chemicals, and moisture, extending the lifespan of the plywood. It's a durable material.

- Water Resistance: The waterproof nature of the film faced plywood makes it ideal for outdoor applications and environments with high humidity.

- Smooth Surface: The smooth film faced plywood is easy to clean and offers a uniform surface for painting or other finishes.

- Strength and Stability: The cross-grain construction of the plywood provides excellent strength and dimensional stability, reducing the risk of warping and splitting. The structural integrity of plywood is critical for applications like concrete formwork.

- Cost-Effectiveness: The long lifespan and reduced maintenance requirements make film faced plywood a cost-effective solution compared to other building materials. Plywood is a versatile product.

- Versatility: Plywood is widely used in construction because it offers a high strength-to-weight ratio.

7. What is the Difference Between Film Faced Plywood and Commercial Plywood?

While both film faced plywood and commercial plywood are made from layers of wood veneer, there are key differences. Commercial plywood, often referred to as ordinary plywood, typically does not have the protective film coating of film faced plywood. This makes it less resistant to water and less durable in harsh environments.

Film faced plywood is a high-quality plywood designed for applications where durability and water resistance are paramount. Commercial plywood is often used for less demanding applications where cost is a primary consideration. Film faced plywood is also easy to cut and is softer.

8. Where Can You Find a Reliable Supplier for High-Quality Plywood?

Finding a reliable plywood supplier is crucial to ensure the success of your projects. When selecting a supplier, consider the following factors:

- Quality: Look for a supplier that offers high-quality plywood, manufactured to meet industry standards. Request samples and inspect them carefully.

- Certifications: Verify that the supplier holds relevant certifications, such as FSC (Forest Stewardship Council) for sustainable forestry practices and CARB (California Air Resources Board) for formaldehyde emission compliance.

- Experience: Choose a supplier with a proven track record and experience in supplying film faced plywood for various applications.

- Pricing: Compare prices from different suppliers, but don't compromise on quality to save a few dollars.

- Lead Times and Logistics: Ensure the supplier can meet your project's timelines and handle logistics efficiently. Ask about their typical delivery schedules and shipping methods.

As an experienced plywood supplier, JsyLVL offers a wide range of high-quality plywood products, including film faced plywood, to meet your construction needs. Our products adhere to rigorous quality control standards, and we have built a solid reputation for reliability and customer satisfaction.

9. What are the Key Applications of Film Faced Plywood?

Film faced plywood is a versatile material used in various construction applications, including:

- Concrete Formwork: This is perhaps the most common application, where film faced plywood provides a smooth, waterproof surface for pouring concrete.

- Flooring: It can be used as a subfloor or for finished flooring in various structures, including trucks and trailers. It can also be used to create durable furniture and shelves.

- Wall Paneling: Film faced plywood is used to create durable and aesthetically pleasing wall surfaces.

- Scaffolding: Its strength and durability make it suitable for scaffolding platforms.

- Transportation: Used for truck and trailer floors due to its abrasion resistance and waterproof nature.

- Marine Applications: Due to its water resistance, it is suitable for marine applications, and ship parts.

10. How Does Film Faced Plywood Perform in Different Environments?

The performance of film faced plywood can vary depending on the environment. In humid or wet environments, the waterproof film coating protects the plywood from moisture damage, ensuring its longevity. In outdoor applications, the film provides excellent resistance to weathering, UV radiation, and temperature fluctuations.

In high-traffic areas, the abrasion resistance of the film protects the plywood surface from wear and tear. With proper care and maintenance, film faced plywood can withstand harsh conditions. The special coating makes it more resistant to water.

Key Takeaways:

- Film faced plywood is a durable, waterproof building material with a protective film coating.

- It is a great option for any construction.

- Birch film faced plywood provides excellent strength and an attractive appearance.

- It is the best option for applications like concrete formwork.

- Choose a reliable plywood supplier like JsyLVL for high-quality products.

- Film faced plywood offers superior durability and water resistance in demanding environments.

Post time: Feb-19-2025