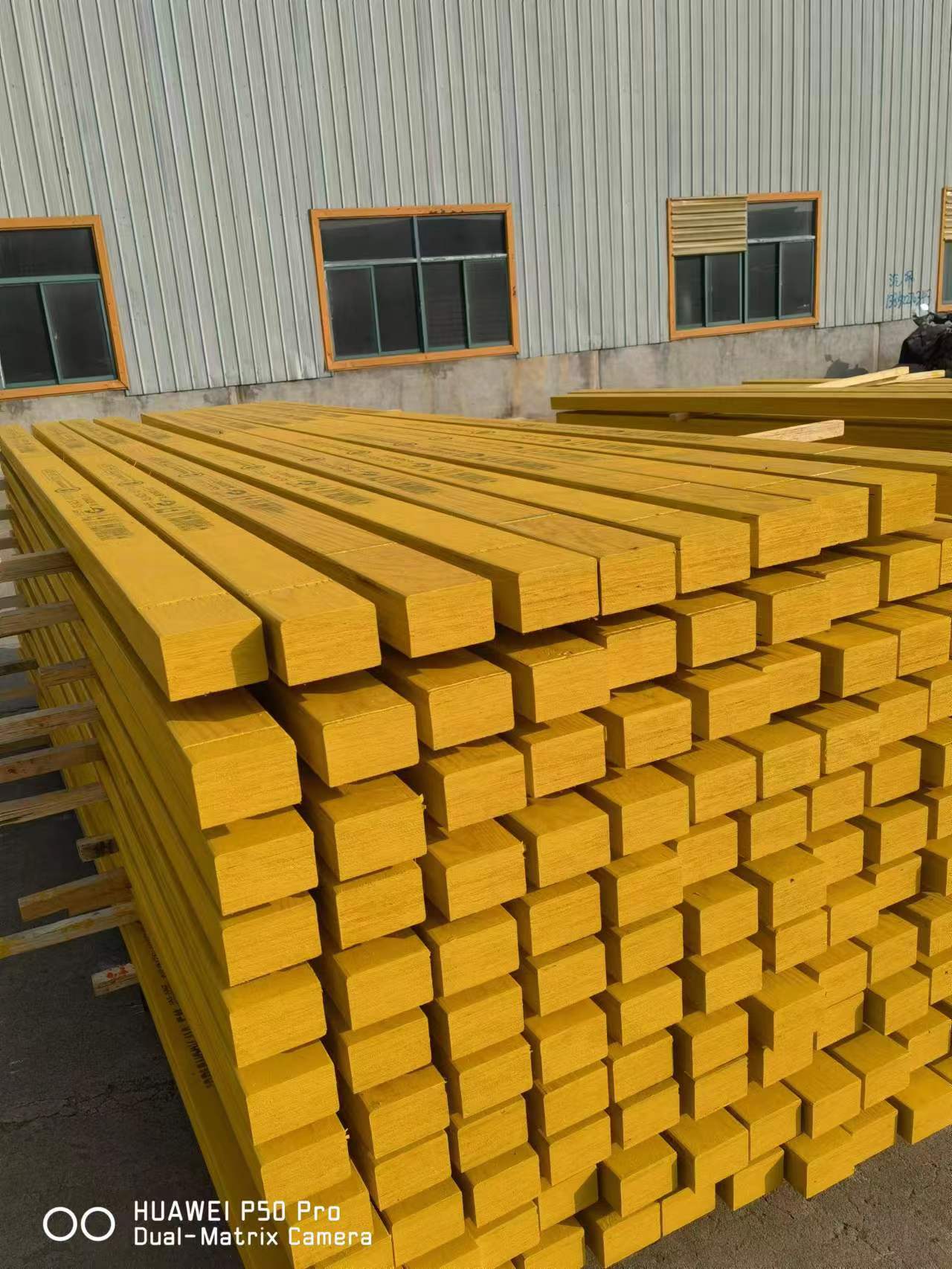

LVL core material, E0 is green and environmentally friendly, and has various uses. It can be used for stairs, doors, door cores, door and window frames, indoor partitions, etc. It can also be used as furniture materials and packaging materials.

Product Description

1. Non-load-bearing structural LVL with diverse uses.

2. The quality is stable, the strength is uniform, and the material variability is small. It is the most ideal structural material to replace logs.

3. Corresponding pretreatment or special adhesives have been carried out during the production process, which has the properties of insect resistance, anticorrosion, fire prevention and water resistance, etc.

4. It has extremely strong shock resistance and shock absorption performance, and resists fatigue damage caused by cyclical stress;

5. We have 15 years of LVL product production experience, a full set of advanced equipment imported from Germany, and complete product certificates.

6. Customize the selection of tree species, size and utilization rate to 100% according to user requirements

Product Parameters

| Place of Origin | Jiangsu, China |

| Main Material | Pine,eucalyptus,Poplar |

| Grade | FIRST-CLASS, Construction |

| Usage | Outdoor |

| Design Style | Contemporary |

| Application | Other, Building Construction |

| Project Solution Capability | graphic design, 3D model design, total solution for projects, Others |

| After-sale Service | Online technical support |

| Warranty | 3 Year |

| Formaldehyde Emission Standards | E0,E1,E2,as request |

| Core | Pine,eucalyptus,Poplar |

| Veneer Board Surface Finishing | Double-Sided Decoration |

| Glue | MR/E0/E1/E2/WBP/Melamine or as request |

| Thickness | ±2.0mm/customized |

| Certification | CE FSC CARB/EPA |

| Moisture | 8-13% |

| SIZE | L≤6000mm,Width can becustomized |

Product Knowledge

1. What is LVL?

LVL is the English abbreviation of Laminated Veneer Lumber. It is made of logs as raw materials by rotary cutting or slicing to make veneers. After drying and gluing, they are assembled according to the grain or most of the grain, and then glued together by hot pressing. sheet.

2. Purpose and classification of LVL?

According to the purpose, it can be divided into packaging level LVL, furniture level LVL and construction level LVL.

3. The purpose of building LVL is naxie?

Structural LVL (load-bearing components): load-bearing structural components including building beams and columns, wooden houses, etc.;

Non-structural LVL (non-load-bearing components): including furniture, stairs, doors, door and window frames, interior partitions, etc.

4.What is the product grade of LVL?

Generally refers to the strength level of LVL, that is, the higher the elastic modulus, the higher the wood strength. F8, F14, F17 are widely used, and F22, F27, etc. are more advanced. In most cases, the LVL of F17 level is Can handle all application scenarios.

5. Compared to solid wood, are there any restrictions on processing or use?

The processing of LVL is the same as that of ordinary solid wood, and it can be sawed, planed, chiseled, tenoned, nailed, etc., without special restrictions.

Product Display & Application