Top Advantages of Opting for Birch Plywood Sheets Over Regular Plywood

Birch plywood sheets are becoming a popular choice in woodworking and construction, and for good reason! This article dives into why opting for birch plywood sheets might be the best decision for your next project. We'll explore the top advantages of this amazing material, comparing it to regular plywood and other wood options, so you can understand exactly why birch plywood is often considered a superior choice. If you're curious about durable, beautiful, and reliable wood for your cabinets, furniture, or construction needs, keep reading to discover the benefits of birch plywood!

1. What is Birch Plywood and Why is it Different from Regular Plywood?

When you hear the term "plywood," you probably think of large sheets of wood used in construction. But not all plywood is created equal! Birch plywood is a special type of plywood known for its high quality and attractive appearance. To understand what makes it different, let's first talk about what plywood is in general.

Plywood is an engineered wood product. This means it's not just one solid piece of wood, like a plank of lumber. Instead, plywood is made from thin layers of wood veneer glued together. These layers, called plies, are stacked with their wood grain running in opposite directions. This cross-graining is what gives plywood its strength and stability. Think of it like a brick wall – the overlapping bricks make it much stronger than just a single layer of bricks.

Regular plywood can be made from various types of wood, often softer woods like pine or fir. This type of plywood is perfectly fine for many construction jobs, but it might not be the best choice when you need something really strong, smooth, and beautiful. That's where birch plywood comes in. Birch plywood is made specifically from birch wood, a type of hardwood. This simple difference in the type of wood makes a huge difference in the final product. Because it uses hardwood, birch plywood inherently becomes a hardwood plywood, offering superior qualities compared to plywood made from softwood.

2. What are the Top Advantages of Birch Plywood?

So, what are the top advantages of opting for birch plywood sheets? There are many reasons why birch plywood has become famous and is often considered a superior plywood choice. Let's break down some of the key benefits:

-

Strength and Durability: Birch is a hardwood, and hardwood is generally stronger and more durable than softwood. Because birch plywood is made from birch veneer, it inherits these qualities. The layers of birch veneer in birch plywood are typically very dense, which contributes to its exceptional strength. This makes birch plywood excellent for projects that need to withstand stress and weight. Its known for its durability in demanding applications.

-

Smooth Surface: Birch plywood is known for its incredibly smooth surface. The birch veneer used on the face of the plywood is usually very fine-grained, creating a surface that is easy to finish and paint. This smooth surface also makes it ideal for applications where appearance is important, such as cabinet doors or furniture. Compared to regular plywood, which can sometimes be rough and splintery, birch plywood provides a much more refined and pleasing surface.

-

Attractive Appearance: Birch wood itself has a light, creamy color and a subtle, attractive wood grain. Birch plywood showcases this natural beauty. The clean, uniform look of birch plywood makes it visually appealing for projects where the wood is visible. It can be easily stained to enhance its natural color or painted for a different aesthetic. Birch plywood lens a stroke of elegance to any woodworking project.

-

Excellent Screw-Holding Properties: Due to its dense layers and hardwood composition, birch plywood has excellent screw-holding properties. This means screws and fasteners will grip firmly into the plywood, creating strong and stable joints. This is crucial in furniture making and construction where secure connections are essential.

-

Dimensional Stability: Like other types of plywood, birch plywood is dimensionally stable. This means it resists warping and twisting better than solid wood. This stability is due to the cross-layered construction, which minimizes the natural movement of wood as it responds to changes in humidity. This dimensional stability makes birch plywood a reliable material in various environments.

These top advantages make birch plywood a fantastic material for a wide range of projects, from simple DIY crafts to complex construction applications.

3. How Durable is Birch Plywood Compared to Other Hardwood Options?

When we talk about durability, it's helpful to compare birch plywood to other wood options, especially solid wood and other types of hardwood. How durable is birch plywood really?

Compared to solid wood, birch plywood often comes out on top in certain aspects of durability. Solid wood, while beautiful, can be prone to warping, cracking, and splitting, especially with changes in humidity. Birch plywood, due to its engineered construction, is much more resistant to these issues. The cross-layered veneers provide dimensional stability that solid wood simply can't match. While an original wood piece of solid birch may seem inherently durable, in large panels, plywood offers superior stability.

In terms of strength, high-quality plywood, including birch plywood, can be surprisingly strong – sometimes even stronger than solid wood of the same thickness, in specific directions of force. This strength-to-weight ratio is another advantage.

Compared to other hardwood options, birch plywood holds its own very well. While some very dense hardwoods like oak or maple might be slightly harder on the Janka hardness scale (a measure of wood's resistance to denting and wear), birch plywood still offers excellent durability for most applications. And when you factor in the advantages of plywood construction – like dimensional stability and resistance to splitting – birch plywood becomes a very competitive hardwood option. For example, while oak is a strong hardwood, oak plywood might not have the same smooth, consistent veneer layers as birch plywood, potentially making birch a better choice for smooth, paintable surfaces.

In terms of longevity, well-made birch plywood furniture or structures can last for decades, rivaling and sometimes exceeding the lifespan of solid wood counterparts, especially in environments with fluctuating humidity. The durability of birch plywood makes it a safe wood option for long-lasting projects.

4. Is Birch Plywood Better for Cabinets and Furniture Making?

For cabinet and furniture making, birch plywood has become a popular choice, and many woodworkers and manufacturers consider it better than plywood made from softer woods, and in some cases, even better than solid wood. Is birch plywood really better for these applications? Let's look at why birch plywood is often favored for cabinets and furniture:

-

Stability for Cabinets: Cabinets, especially kitchen cabinets, need to be sturdy and resist warping over time. The dimensional stability of birch plywood is a huge advantage here. Cabinet boxes made from birch plywood are less likely to warp or sag compared to those made from solid wood or lower-grade plywood, ensuring drawers and doors continue to operate smoothly for years.

-

Smooth Paintable Surface for Furniture: For painted furniture, the smooth surface of birch plywood is ideal. It requires less prep work to achieve a flawless painted finish compared to more porous woods or rougher plywood types. This makes it perfect for modern, painted cabinet styles and furniture where a smooth, even color is desired. Birch plywood allows for beautiful, painted cabinet finishes.

-

Strength for Drawers and Shelves: Drawers and shelves need to be strong enough to hold weight without bending or breaking. Birch plywood provides the necessary strength and rigidity for these components. For drawer boxes, in particular, the excellent screw-holding properties of birch plywood create strong, durable joints that can withstand daily use.

-

Cost-Effectiveness: While birch plywood might be slightly more expensive than regular plywood made from softwood, it is often more cost-effective than using solid hardwood for entire cabinet or furniture pieces. Using birch plywood allows you to achieve a high-quality, hardwood look and feel without the high price tag of solid hardwood. This cost-effectiveness makes birch plywood a smart choice for large projects like kitchen renovations.

-

Versatility in Design: Birch plywood is versatile in terms of design. It can be easily cut, shaped, and joined to create various furniture styles. Whether you're building modern minimalist cabinets or more traditional furniture pieces, birch plywood can adapt to different design aesthetics. Its neutral color and clean grain also make it a great base for different finishes and styles.

Because of these benefits, birch plywood is often used in making high-quality cabinets, drawers, shelves, and various types of furniture. It strikes a great balance of durability, beauty, and cost, making it a smart choice for both professional furniture makers and DIY enthusiasts.

5. What Makes Baltic Birch Plywood So Special?

You might have heard the term "Baltic birch plywood" and wondered what makes it different. Baltic birch plywood is a specific type of birch plywood that is highly regarded for its exceptional quality. What makes Baltic birch plywood so special compared to regular birch plywood?

-

All Birch Veneer Core: One of the key features of Baltic birch plywood is that it is made entirely of birch veneer, even in the core layers. Many other types of plywood, including some birch plywood, might use a different, less expensive wood species for the inner plies. This all-birch construction gives Baltic birch plywood superior strength, stability, and edge quality.

-

More and Thinner Plies: Baltic birch plywood typically has more plies than standard plywood of the same thickness, and these plies are thinner. For example, a ¾" sheet of Baltic birch might have 13 plies or more, while regular plywood might have fewer. These extra layers of thin birch veneer create a very dense, void-free core.

-

Void-Free Core: The term "void-free" is crucial when talking about Baltic birch. Voids are gaps or holes in the inner layers of plywood, which can weaken the material and create problems when cutting or shaping edges. Baltic birch plywood is manufactured to have virtually no voids in its core. This results in clean, solid edges that are ideal for joinery and exposed edges in furniture. The edges of Baltic birch plywood are highly prized for their appearance and strength.

-

Consistent Thickness and Quality: Baltic birch plywood is known for its consistent thickness and high manufacturing standards. This reliability in dimensions and quality is very important for precise woodworking and manufacturing processes. When you buy Baltic birch, you can generally rely on it to be consistently flat, straight, and of uniform thickness throughout the sheet.

-

Superior Edge Appearance: Because of its all-birch core and void-free construction, the edges of Baltic birch plywood are exceptionally clean and attractive. They can be finished beautifully with just a clear coat, showcasing the layers of birch veneer. This makes Baltic birch plywood a favorite for projects where the edges are meant to be seen, like exposed joinery or layered designs.

While Baltic birch plywood is generally more expensive than other types of birch plywood or regular plywood, its superior qualities make it worth the investment for projects where strength, stability, edge quality, and appearance are paramount. Many woodworkers use baltic birch for high-end furniture, cabinet components, and jigs and fixtures where precision and reliability are essential.

6. Are There Any Cons of Using Birch Plywood? What are the Disadvantages of Birch Plywood?

While birch plywood offers many advantages, it's important to consider if there are any cons of using birch plywood. Like any material, birch plywood has some potential disadvantages that are worth noting before you decide if it's the right choice for your project. Let's explore some of the potential downsides:

-

Cost: One of the primary disadvantages of birch plywood, especially Baltic birch, is its cost. Birch plywood is generally more expensive than regular plywood made from softwood. Baltic birch, with its premium qualities, is at the higher end of the plywood price spectrum. For large projects, the cost of birch plywood can add up significantly. If budget is a major constraint and you don't need the specific benefits of birch, regular plywood might be a more economical choice. The cost of birch plywood can vary depending on grade, thickness, and source.

-

Availability: Depending on your location and the type of birch plywood you need (especially Baltic birch), availability can sometimes be a factor. While birch plywood is becoming more widely available, it might not be as readily stocked at every home improvement store compared to common softwood plywood. Baltic birch, in particular, might require sourcing from specialty lumber suppliers, which could mean longer lead times or needing to place a special order.

-

Stain Grade Variation: While birch plywood is known for its smooth surface and ability to take stain well, birch wood itself can sometimes have variations in color and grain. This means that when you stain birch plywood, you might see some slight unevenness in the stain absorption, especially across large surfaces. While this can sometimes add to the natural character of the wood, if you are aiming for a perfectly uniform, deep stain color, you might need to take extra steps like using a wood conditioner or toner. However, for many, the natural stain acceptance of birch is still considered an advantage.

-

Not Ideal for Outdoor Use (Untreated): Like most plywood types, unless specifically treated or designed for exterior use (like marine plywood which sometimes uses birch), birch plywood is not inherently weather-resistant. Exposure to moisture and the elements can cause it to delaminate and degrade over time. For outdoor projects or applications where plywood will be exposed to moisture, it's essential to use pressure-treated plywood or marine plywood designed for those conditions. Regular birch plywood is best suited for interior applications. You can find marine plywood options that utilize birch for enhanced water resistance.

Despite these potential disadvantages, for many applications, the advantages of birch plywood often outweigh the cons, especially when quality, durability, and appearance are top priorities. Understanding these potential downsides helps you make an informed decision when choosing plywood options for your projects.

7. How Does the Cost of Birch Plywood Compare to Regular Plywood and Solid Wood?

The cost of materials is always a significant factor in any project. So, how does the cost of birch plywood stack up against regular plywood and solid wood? Let's break down a cost comparison:

-

Birch Plywood vs. Regular Plywood: In general, birch plywood is more expensive than regular plywood made from softwood species like pine or fir. The price difference can vary, but you can typically expect to pay 20-50% more for birch plywood compared to a similar thickness of softwood plywood. This price difference reflects the higher quality hardwood veneer, denser core, and often better manufacturing standards of birch plywood. For projects where strength, smoothness, and appearance are important, many consider the extra cost of birch plywood to be a worthwhile investment.

-

Baltic Birch Plywood vs. Regular Birch Plywood: Baltic birch plywood is typically the most expensive type of birch plywood. Due to its all-birch veneer core, void-free construction, and premium quality, Baltic birch can cost significantly more than standard birch plywood. The price premium for Baltic birch can range from 30-70% or even more compared to regular birch plywood, depending on thickness and supplier. Baltic birch is a premium product, and its price reflects its superior qualities.

-

Birch Plywood vs. Solid Wood: When comparing birch plywood to solid hardwood lumber, the cost comparison becomes more complex and depends on several factors:

- Material Cost: For large panels, birch plywood is almost always more cost-effective than buying solid hardwood lumber in comparable dimensions. Solid hardwood lumber is sold by the board foot and can be very expensive, especially for wider boards needed for panels. Birch plywood provides large, consistent sheets at a lower material cost than solid hardwood panels.

- Labor and Waste: Using solid wood to create large panels often involves joining multiple boards together, which requires extra labor, specialized equipment (like jointers and planers), and can generate more waste wood. Birch plywood comes in ready-to-use sheets, reducing labor and waste.

- Stability and Performance: As discussed earlier, birch plywood is often more dimensionally stable than solid wood. For applications where warping or movement is a concern, birch plywood can be a more reliable and ultimately cost-effective choice in the long run, as it reduces the risk of material failure or rework.

To summarize, while birch plywood is more expensive than regular softwood plywood, it is often more cost-effective than using solid hardwood for large panels and offers performance advantages in terms of stability. Baltic birch plywood is the premium option with the highest cost but also the highest quality. When buying birch plywood, consider your project requirements and budget to determine the best type of plywood for your needs.

8. Where Does Birch Plywood Source its Wood From and is it Sustainable?

Understanding the source of your wood products and whether they are sustainably sourced is increasingly important. Where does birch plywood come from, and is it a renewable source of wood?

-

Primary Source: Birch Trees: As the name suggests, birch plywood is made from birch trees. The type of birch used most commonly for plywood is typically birch lumber harvested from forests in regions where birch trees are abundant.

-

Regions of Birch Sourcing: Major regions for birch plywood production and sourcing include:

- Russia: Russian birch, also known as European birch, is a significant source for Baltic birch plywood and other high-quality birch plywood. Forests in Russia contain vast birch resources.

- Northern Europe: Countries like Finland, Latvia, and Estonia are also important sources of birch for plywood production, particularly for Baltic birch.

- North America: Birch trees also grow in North America, and some birch plywood is produced in the USA and Canada, often using birch sourced from domestic forests.

- China: China has become a major producer of various types of plywood, including birch plywood. They source birch from domestic forests and import from regions like Russia. Our factory, JsyLVL, is based in China and utilizes sustainably sourced birch for our plywood production.

-

Sustainability Considerations: Birch is generally considered a relatively fast-growing and renewable source of wood. When sourced from responsibly managed forests, birch plywood can be a sustainable wood product. Here are some factors related to sustainability:

- Forest Management Practices: The key to sustainable sourcing is responsible forest management. This includes practices like replanting trees, selective harvesting, protecting biodiversity, and ensuring the long-term health of forests. Look for certifications like FSC (Forest Stewardship Council) that indicate the wood comes from responsibly managed forests.

- Renewable Resource: Birch trees mature relatively quickly compared to some other hardwoods, making them a more rapidly renewable resource. Sustainable forestry practices focus on managing birch forests to ensure continuous harvests without depleting the resource.

- Engineered Wood Efficiency: Plywood, as an engineered wood product, is generally more efficient in its use of wood fiber compared to solid lumber. Plywood production utilizes more of the tree, reducing waste.

When buying birch plywood, especially if sustainability is a concern, look for information about the source of the wood and any certifications related to sustainable forestry practices. Choosing plywood made from sustainably sourced birch supports responsible forest management and helps ensure that birch remains a renewable wood option for future generations. We at JsyLVL are committed to sustainable practices and offer environmentally friendly plywood options.

9. Using Birch Plywood: What Kind of Projects is it Best Suited For?

Birch plywood's unique combination of properties makes it well-suited for a wide range of projects. But what kind of projects is birch plywood best suited for? Here are some ideal applications for using birch plywood:

-

High-Quality Cabinets and Furniture: As discussed earlier, birch plywood is excellent for cabinet boxes, drawer boxes, shelves, and furniture frames. Its stability, strength, smooth surface, and paintability make it a top choice for kitchen cabinets, built-ins, dressers, tables, and desks. For high-end plywood furniture, Baltic birch is often preferred.

-

Interior Architectural Millwork: Birch plywood is used for interior architectural details like wall paneling, wainscoting, decorative trim, and built-in shelving units. Its attractive appearance and smooth surface lend themselves well to visible architectural elements.

-

Jigs and Fixtures for Woodworking: Woodworkers often use Baltic birch plywood to make jigs, fixtures, and templates for woodworking. Its dimensional stability, flatness, and void-free edges make it ideal for creating precise and reliable shop aids.

-

Laser Cutting and CNC Projects: Birch plywood, particularly Baltic birch, is a favorite material for laser cutting and CNC machining. Its consistent thickness, void-free core, and clean edges result in precise and high-quality laser-cut parts and CNC-milled components. It's used for everything from decorative items to mechanical parts.

-

Children's Toys and Educational Materials: Due to its smooth surface, durability, and non-splintering nature (especially Baltic birch), birch plywood is often used to make children's toys, puzzles, and educational materials. It's considered a safe wood option for these applications.

-

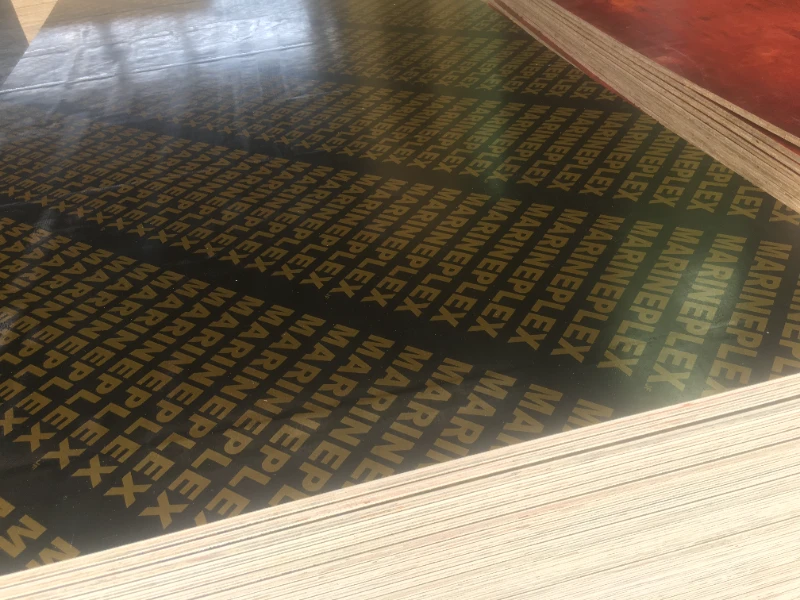

Formwork and Concrete Forms: Film faced plywood, including birch plywood with a phenolic film coating, is used for concrete formwork. The smooth, durable surface of film faced plywood creates smooth concrete finishes. While birch might not be the most common species for formply, high-quality film faced birch plywood offers excellent performance for concrete forming. Formply F17 2400x1200x17mm and Concrete Formwork LVL E11 are related products you might consider for concrete projects.

-

Flooring Underlayment: While not typically used as a finished flooring surface itself (except for some specialty applications), birch plywood can be used as a high-quality underlayment for flooring. Its flatness and stability provide a solid base for finished flooring materials. Consider our range of Oak flooring and Solid wood flooring options for your finished floor.

These are just some of the many projects where birch plywood excels. Its versatility and desirable properties make it a valuable material for both professional and DIY applications.

10. Choosing Plywood: Is Birch Plywood the Right Choice for You?

Choosing the right type of plywood for your project is crucial for success. After exploring the advantages and considerations of birch plywood, the question remains: is birch plywood the right choice for you? Here's a quick guide to help you decide when opting for birch plywood sheets is the best decision:

Choose Birch Plywood If:

- High Quality Finish is Important: You need a smooth, paintable, or stainable surface for cabinets, furniture, or visible architectural elements.

- Strength and Durability are Key: Your project requires strong, stable panels that can withstand stress and resist warping, like cabinet boxes, drawers, shelves, or structural components in furniture.

- Edge Appearance Matters: You want clean, attractive edges that can be left exposed or finished with a clear coat, especially for joinery details or layered designs (Baltic birch is ideal for this).

- Precise Machining is Needed: You are using laser cutting, CNC machining, or require very accurate dimensions for jigs, fixtures, or components.

- You are Making Toys or Children's Items: Safety and a smooth, non-splintering surface are important for toys and educational materials (Baltic birch is a great choice here).

- You are Building High-End Projects: For projects where quality and longevity are paramount, and budget allows for a premium material, birch plywood, especially Baltic birch, is an excellent investment.

Consider Alternatives If:

- Budget is the Top Priority: If your project is very budget-constrained and high-end appearance or maximum strength are not critical, regular softwood plywood might be sufficient.

- Outdoor or High-Moisture Use: For projects exposed to weather or constant moisture, pressure-treated plywood or marine plywood specifically designed for exterior use are necessary. Untreated birch plywood is not suitable for these conditions.

- Rough or Rustic Look is Desired: If you are going for a very rustic or textured look, the smooth, refined surface of birch plywood might not be the aesthetic you are aiming for. Other wood types with more pronounced grain or texture might be more appropriate.

Ultimately, choosing plywood involves balancing your project requirements, budget, and desired outcome. Birch plywood stands out as a superior plywood choice for many applications, offering a compelling combination of beauty, strength, and versatility. By carefully considering your needs and the advantages of opting for birch plywood sheets, you can make the best decision for your woodworking or construction project.

Key Takeaways: Advantages of Birch Plywood

- Superior Strength and Stability: Hardwood birch veneers and cross-layered construction provide exceptional strength and resistance to warping.

- Beautiful Smooth Surface: Ideal for painting, staining, and clear finishes, offering a refined look for cabinets and furniture.

- Excellent Screw Holding: Dense layers ensure strong and secure joints, crucial for furniture and structural applications.

- Versatile Applications: Suitable for cabinets, furniture, millwork, laser cutting, jigs, toys, and more.

- Sustainable Option: Birch is a renewable resource, and responsibly sourced birch plywood supports sustainable forestry.

- Baltic Birch Excellence: The premium choice for void-free cores, superior edge quality, and ultimate stability.

Post time: Jan-23-2025