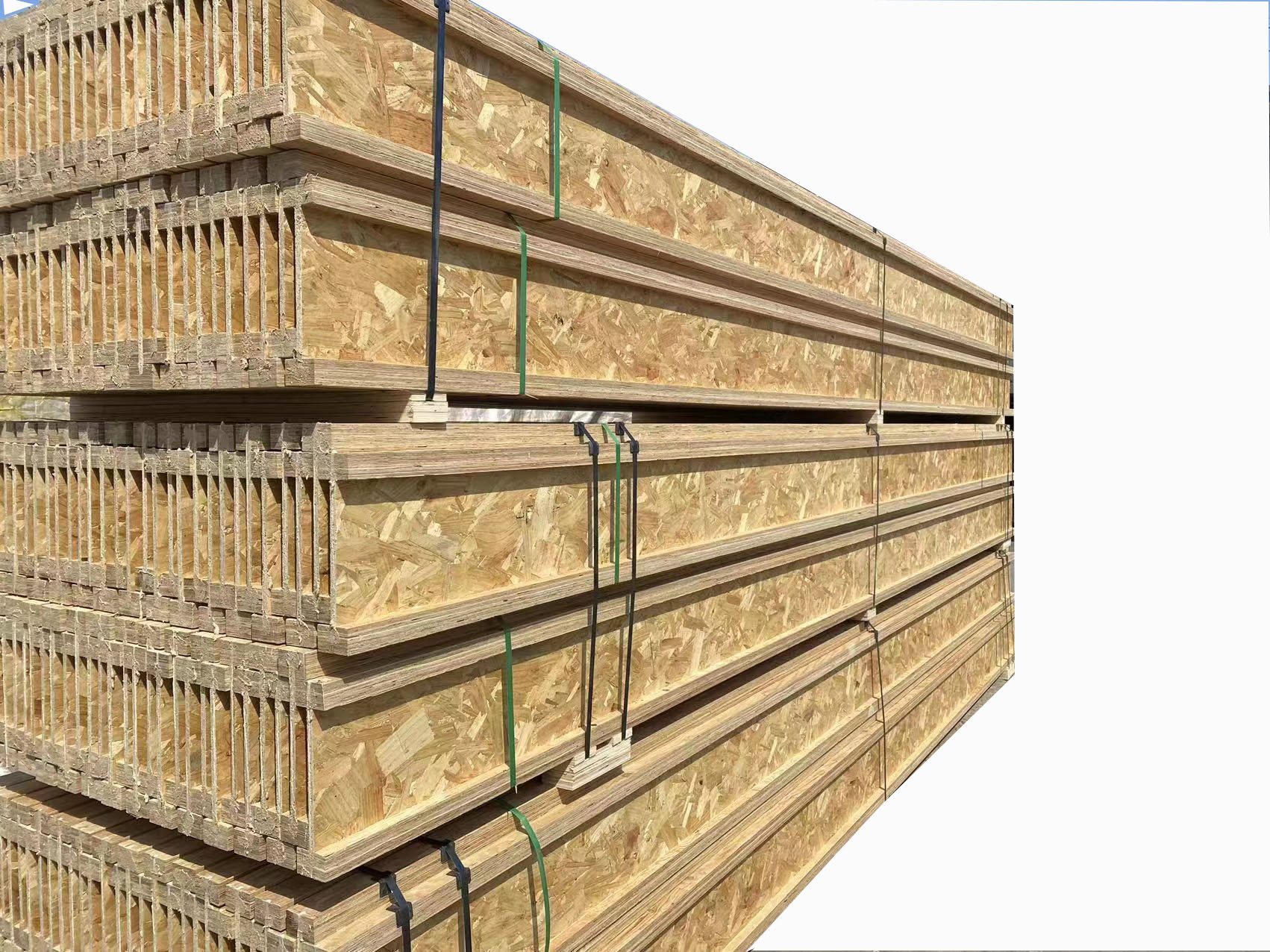

E0 environmental protection structural plywood, Japanese JAS standard, Australian AS/NZS2269 standard, American plywood standard, with complete qualifications and stable quality.

Product Description

1. Stable quality, green and environmental protection, strict implementation of structural plywood production standards.

2. Smooth surface, clear texture, strong bending resistance.

3. The vertical bending strength is uniform, the elastic modulus is high, and the load-bearing effect is better.

4. Mainly used for building load-bearing components, both indoors and outdoors.

5. We have 20 years of production experience in plywood products, a full set of advanced equipment imported from Germany, and complete product certificates.

6. The tree species and size can be customized according to user requirements, and the utilization rate can reach 100%.

Product Parameters

| Place of Origin | Jiangsu, China |

| Main Material | Pine,eucalyptus, Poplar |

| Grade | FIRST-CLASS, Construction |

| Usage | Outdoor |

| Design Style | Contemporary |

| Application | Other, Building Construction |

| Project Solution Capability | Graphic design, 3D model design, total solution for projects, Others |

| After-sale Service | Online technical support |

| Warran ty | 3 Year |

| Formaldehyde Emission Standards | E0,E1,E2,as request |

| Core | Pine,eucalyptus, Poplar |

| Veneer Board Surface Finishing | Double-Sided Decoration |

| Glue | MR/E0/E1/E2/WBP/Melamine or as request |

| Thickness | ±0.50mm/customized |

| Certification | CE FSC CARB/EPA BSI-AS/NZS4357 |

| Moisture | 8-13% |

| SIZE | L≤2440mm,W≤1220mm |

Product Knowledge

1. What is structural plywood?

Plywood has good water resistance, moisture resistance, sufficient strength and stiffness, and can be used as a stressed member. As an important building material, it is widely used in construction, furniture manufacturing, vehicles, ships and other fields.

2. What are the important indicators of structural plywood?

Moisture content: indicates the percentage of moisture contained in the plywood; density: indicates the weight per unit volume of the plywood; bending strength: indicates the bearing capacity of the plywood under bending; shear strength: indicates the bearing capacity of the plywood under shearing; intrinsic Bond strength: Indicates the bonding strength between the layers inside the plywood; Board surface flatness: Indicates the flatness of the plywood surface.

3. How to judge the quality of plywood from the appearance?

The wood grain of good-quality plywood is relatively clear, and it feels smooth and flat, without cracking and other phenomena. The core is an important factor that determines the quality of the plywood. It can be tapped by hand. If the sound is uneven, it means that the core is hollow.

4. About the moisture content of plywood?

The moisture content of the board is very important. If the moisture content is too high, the board is prone to cracking and deformation.

5. What are the differences in adhesives?

There are three main types of plywood adhesives used in plywood production. Melamine glue: moisture-proof, and has a certain resistance to boiling and weathering, and cannot be frequently soaked in water. Phenolic glue: extremely excellent water resistance and weather resistance. Urea-formaldehyde glue: moisture-proof glue, can not be used outdoors, less used.

Product Display & Application