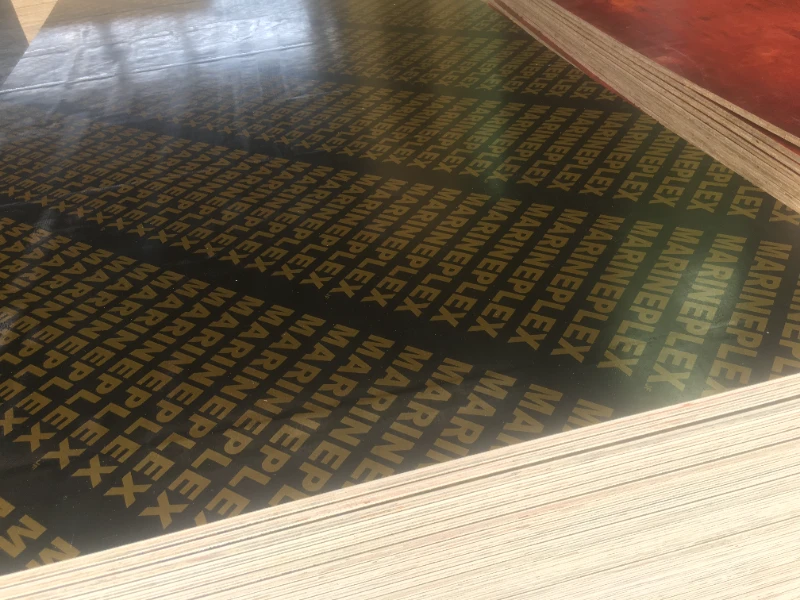

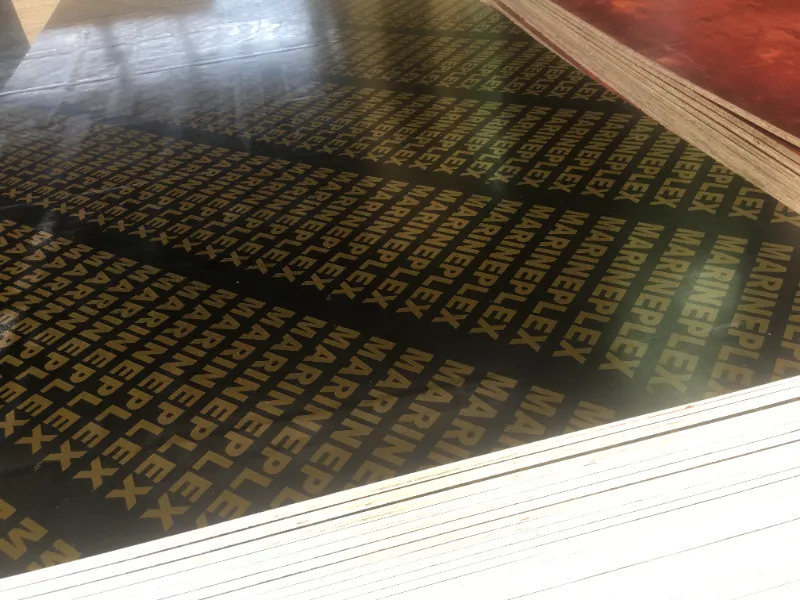

One-time molding/two-time molding, a variety of colors and specifications are optional, completely waterproof, the surface is smooth and does not stick to cement, and the construction is convenient and quick.

Product Description

1. According to different specifications, the number of repeated use can reach 15-40 times.

2. The quality is stable, the surface is smooth and does not stick to cement, and does not need to be cleaned.

3. Strong anti-deformation ability and good waterproof performance. Using phenolic glue can make it completely waterproof.

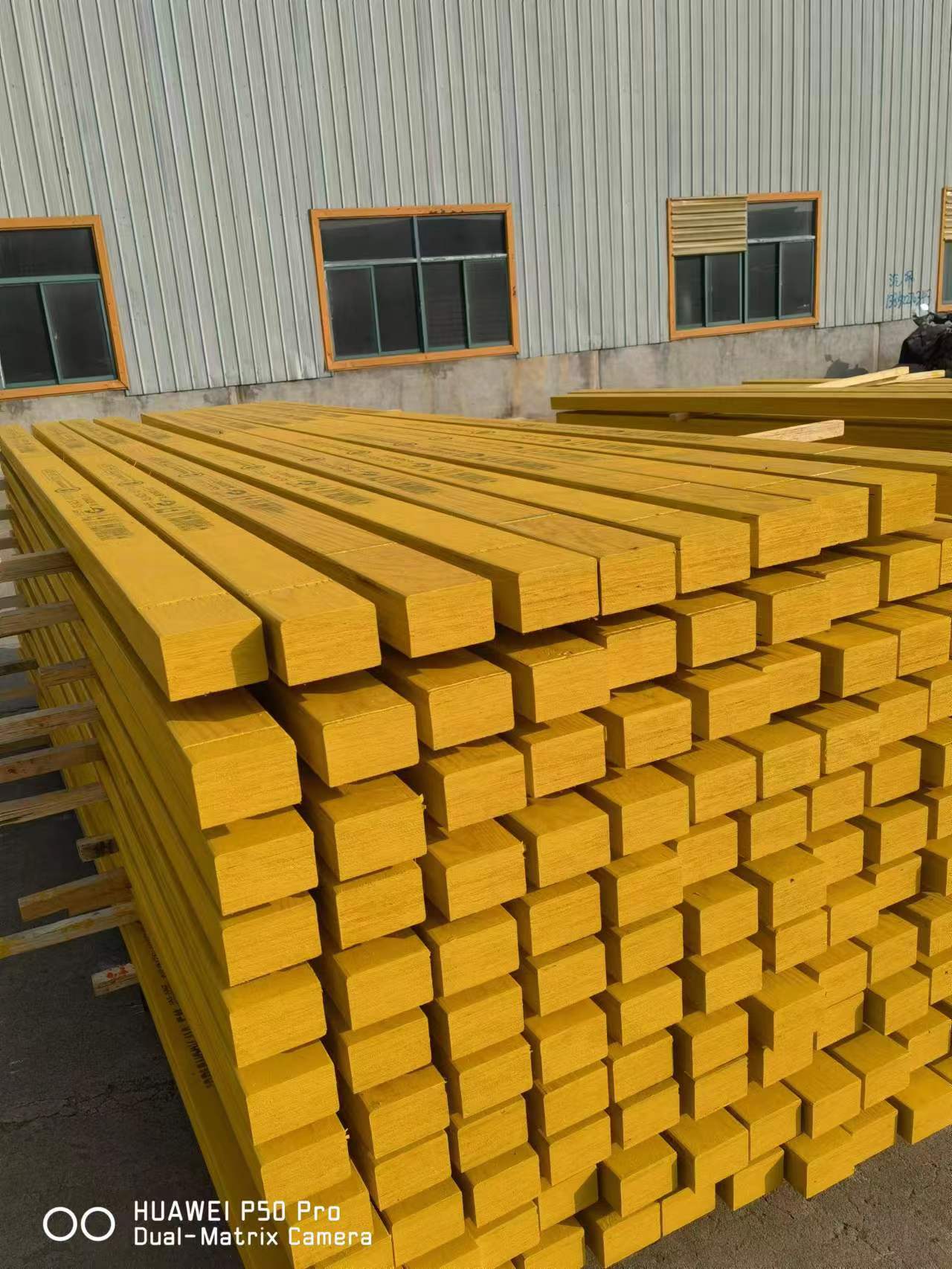

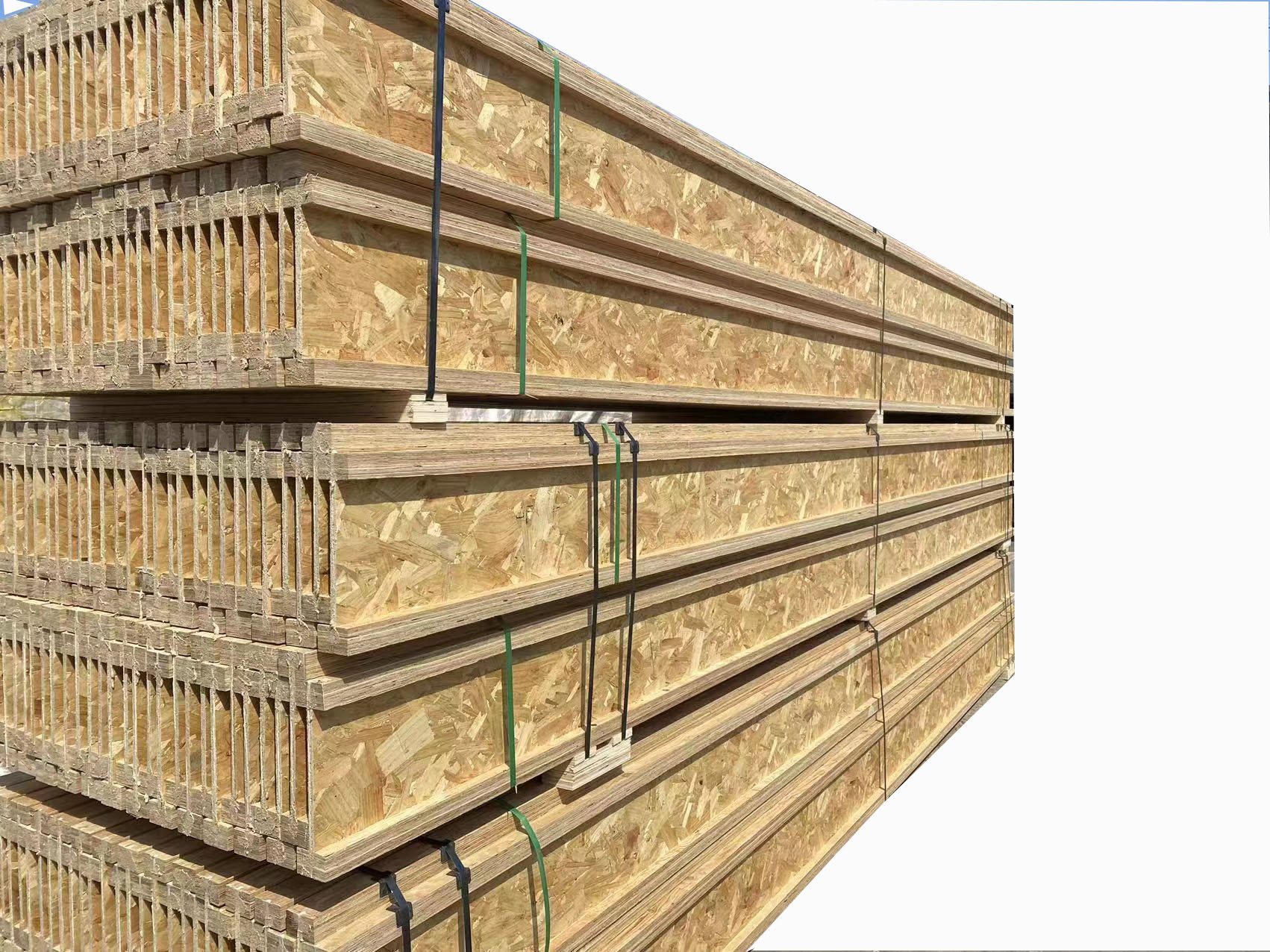

4. Light weight and low density, simple and fast construction, and the laying time is shortened by more than 40%.

5. We have 20 years of production experience in plywood products, a full set of advanced equipment imported from Germany, and complete product certificates.

6. Customize the selection of tree species and glue according to user requirements, and the utilization rate reaches 100%.

Product Parameters

| Product name | Film faced plywood |

| Brand Name | bbm |

| Place of Origin | Jiangsu, China |

| Main Material | Larch,radiata pine,eucalyptus,Poplar |

| Grade | Construction |

| Usage | Qutdoor |

| Design Style | Contemporary |

| Application | Other, Building Construction |

| Project Solution Capability | graphic design, 3D model design, total solution for projects, Others |

| After-sale Service | Online technical support |

| Warranty | 3 Year |

| Formaldehyde Emission Standards | E0,E1,E2,as request |

| Core | Pine,eucalyptus,Poplar |

| Veneer Board Surface Finishing | Double-Sided Decoration |

| Glue | MR/EO/E1/E2/WBP/Melamine |

| Thickness | 12mm-18mm or customize |

| Certification | CE FSC |

| Moisture | 8-13% |

| SIZE | 1220 mm*2440 mm,915 mm*1830 mm |

Product Knowledge

1. What are the advantages of film faced plywood products?

Compared with other laying methods, film faced plywood is light in weight and low in density, and the construction is simple and convenient to carry, which can save more than 40% of the construction period. Compared with traditional construction plywood, film faced plywood can save more than half of the material used, and can also reduce the use of steel nails and wood, so it is a very good choice.

2. Common specifications of film faced plywood market.

Conventional size: 2500mm*1250mm, 2440mm*1220mm, 915mm*1830mm

Common tree species: poplar, pine, birch

3. About the role of surface material?

The laminated board has bright luster and can be selected from a variety of designs and colors. It is waterproof and fireproof, has excellent wear resistance, corrosion resistance and excellent anti-fouling ability, and has excellent anti-ultraviolet performance.

4. Precautions for handling and storing plywood

When it needs to be transported by machinery, it should be carefully bundled, and the soft material on the pad can prevent damage to the board surface; it needs to be protected from long-term sun and rain, so the place where it is placed must be flat and dry, but not very Hot or too dry environment, so as to effectively avoid the deformation and aging of the board.

5. How to understand the lamination process?

The lamination process is the surface processing process after printing. It refers to the product processing process that uses a laminating machine to cover a layer of 0.012-0.020mm thick transparent plastic film on the surface of the printed matter to form a paper-plastic one.

Product Display & Application